by Ted Edge

This is the 50th year celebration of the July 16th, 1969 launch of Apollo 11 and transport of three U.S. Astronauts; Neil Armstrong, Edwin “Buzz” Aldrin, and Michael Collins to the moon and safely returning them back to earth. I have recently twice seen the new Apollo 11 (2019) movie taken from vintage high-quality mages recorded by the astronauts and also taken at Launch Control at (KSC) Kennedy Space Center and Mission Control at (JSC) Johnson Space Center. It was a fantastic movie that kept you in its grip even though you knew the successful outcome of the first mission to the moon. The movie of course does not give (MSFC) Marshall Space Flight Center the credit it deserves but by now hopefully everyone has learned the Saturn 5 vehicle design and all of the smoke and fire with its 7.5M lbs. of thrust and the (IU) Instrument Unit to control it was developed at MSFC.

I am writing these memories not because I contributed anything significant to the Saturn program but because I was given the opportunity by way of being fortunate, timing, coincidence, training, desire, perseverance, or other to be a tiny part of one of the greatest adventures conceived or attempted in the history of man. A nation that would set such a challenge before its citizens and be willing to fund it and gather the talent to organize, plan, engineer, and follow through with tenacity to execute the plan successfully with startling success is truly amazing. Some of the greatest minds and skilled hands and talented bodies came together giving of themselves in making personal sacrifices in executing the plan in the belief that it could be done and done successfully. Opportunities to meet and shake hands and work with and learn from some of these great minds and disciplined talented people have left lasting memories and mental visions of what can be accomplished when both physical and spiritual forces appear to coincide toward achieving a stated goal defined to be one of to go in peace for the good of all mankind.

I was asked by Charlie Dischinger, an MSFC employee at the request of Jack Stokes if I had any historic Saturn Apollo program documents to share with the (UAH) University of Alabama in Huntsville history office library. I looked through our library and did not find any in our home. The searching started me thinking about the work I was doing at MSFC during the Saturn Apollo years and any that might be of note. As I pondered the question, memories began to come back as I located a few Saturn program documents on the internet connected to the work that I was involved with during those years. I decided to write the memories down for our children, grandchildren, and others who might have an interest.

I started work at MSFC in 1965 in the Astrionics Laboratory shown in the lead photograph with Dr. Walter Haeussermann (dec) as Laboratory Director, Hermann Weidner (dec) as (S&E) Science and Engineering Director, and Dr. Wernher von Braun (dec) as MSFC Center Director. Never in my wildest dreams could I have imagined that I would remain at MSFC assigned to the Astrionics laboratory and continue to work and enjoy it for the next 46 years but that is the reality. When I started my tour the Astrionics laboratory had armed MP’s (Military Police) guarding each entry gate as security was taken seriously. I was processed in as a black badge but in time was investigated and upgraded to a red secret clearance keeping it until I retired. The upper management positions at that time were filled by the Germans who had a distinctive cultural aire about themselves that you had to become accustomed to and accept. Most of the management under the Germans were Americans, many of whom were military service veterans but the laboratory seemed to function smoothly and few open comments were said about it. I am sure there was some resentment as many employees had friends and family members who had been killed during the war. But we were now “bogged” down in a war in Vietnam and in a cold war with Russia and in a hot race to reach the moon first where the talents of Americans and Germans working together were desperately needed. I was expecting to be drafted into military service after graduation but was given a deferment by NASA due to the need for engineering skills in the space program. The German rocket team held the knowledge base to bring American rocketry into a working reality. Dr. von Braun (dec) was brilliant technically and had a good personality as well for interfacing and he seemed to keep the center focused on its assigned tasks and goals as he managed both the technical and political sides. The management structure began to change within a few years for the Astrionics Laboratory with the selection of an American, Mr. F. Brooks Moore as the Astrionics Laboratory Director. He was highly capable technically and a good manager and worked well with the German upper management. I was assigned to the Electronics Research Division under Mr. James (Jim, “Tex”) Taylor (dec) and to the Applied Research Branch under W.(Bill) J. Kreider (dec) and Jake Snellgrove (dec) as deputy. The Branch had technical support from the Division in J.(John) M. Gould (dec), R. (Bob) F. Harwell, W.A.(Bert) E. Willis(dec) and C.(Carl)E. Winkler(dec). Thelma Robb and Martha McCartney (dec) were the Division secretaries. The Branch was located in Building 4487, C-wing east, 1st floor and I was assigned to work in a laboratory in room C-160. When I walked into the laboratory and looked it over I realized it was a “laboratory of dreams”. I have repeatedly told others that I would have paid to work in C-160 if I had any money but as a newly graduated Electrical Engineer from (TTU) Tennessee Technology University I had little money but I did have enthusiasm and interest in the NASA-MSFC space exploration program. The peaceful exploration of space to probe the mysteries of the universe for scientific reasons appealed to me personally and also in believing the findings would help reveal the relationship without contradiction to our Creator’s majestic work that He had declared as Good. Space exploration had excited me from the night I looked through a telescope at the moon and planets in the domed Rice Observatory at Cumberland University in Lebanon, TN. I was also an Amateur (HAM) radio operator (WN4DOW), habitual electronic tinkerer, science and religion ponderer while anchored in the Biblical faith instilled in me by my father and mother. The laboratory was a hands-on laboratory with cabinets full of the latest semiconductor technology components, vector boards, wire racks, Tektronix test equipment, Tenney thermal chamber, design handbooks, friendly knowledgeable engineers and technicians, hand tools, work benches, a nearby transformer winding shop and a BC-wing flight hardware parts store with a simple charge code Saturn 5. There was a snack cart, a snack bar, vending machines and a cafeteria in the building. The laboratory was self contained with hallway bells sounding the start and stop times of the work day. Most everyone spent the day at their laboratory work station or at their desk and few people entered and left the laboratory during the day. Every engineer had a desk and a telephone for local calls with all long distance calls required to go through the Division secretary. Everyone received the bi-weekly Marshall Star, a publication of the good news going on at the center with a blue insert with technical information on an ongoing NASA project. There was usually one junior walled office in the laboratory occupied by a lead engineer. There were supporting contractors in the Astrionics laboratory with separate offices. The Astrionics laboratory was a beehive of activity working Saturn 5 avionics tasks with crowded offices and busy hallways. There were weekly Branch meetings for discussing tasks and progress. It was a good working environment and it did not take long to make friends and some of them become lifetime friends. I played softball in the (MARS) Marshall Athletics league and lifted weights with laboratory friends after work. It was the era of rockets, Beach Boys music, muscle cars and Corvettes and I enjoyed a red 1966 model. The work tasks that were ongoing in the C-160 laboratory were power supply design (DC to DC converters) and power inverter design (DC to AC converters) and their prototyping for use in ground support equipment and for space flight. The laboratory also maintained and tested inverters previously installed in applications when necessary. I was blessed to be given a laboratory that was supported by Mr. Elbern Lentz (dec), a middle aged veteran who had a heart of gold for helping a young engineer and was himself a good hands-on practical technician and knew where everything was that we needed. During breaks he would entertain us with tales from his Red Bay, Alabama hometown where he once operated a Radio-TV repair shop. Dr. Walter Haeussermann (dec) tried to run a well disciplined laboratory. Elbern Lentz (dec) told me he was once “fussed at” by him for reading a newspaper at lunch time in that it was a waste of time and he should be reading a technical journal instead. I had no experience in designing electronic circuits that were space qualified or man rated but I was eager to learn. I rolled my sleeves up and got involved doing assigned work and supporting the Saturn Apollo program until its completion with the (Orbital Workshop) OWS/SKYLAB. I was first assigned a task to design a low voltage DC to DC converter for a ground support application. Then through some management route I was asked to design a 28VDC to 1000VDC power supply for a balloon experiment for Wally Parker in the (SSL) Space Science Laboratory. I had been shocked by 250VDC from the B+ of a radio power supply but 1000VDC shook me hard enough that I started practicing the advice of nearby laboratory technician Billy Dunn (dec) who told me to keep one hand in your pocket when probing into a 1000 VDC power supply breadboard. Billy Dunn (dec) was an Army veteran and was tough on young engineers. He would advise me to wave my degree at it if I was stuck on a problem where I needed help. After a good laugh he would usually bail me out of my problem. I was given a task of designing a 100 Watt 115VAC sine wave low distortion output inverter for a Mr. Hoop to power a bone density sensor for a bio-medical experiment on the OWS/SKYLAB program. A tuned series pass filter and a parallel shunt filter were used to extract sine wave power from the square wave switching front end of the inverter. Hand wound filter magnetic were used that required removing or adding one turn at a time until the sine wave output harmonics were correct. Theory and calculations can you get close to a solution but sometimes fine tuning is required by the designer or technician to get it correct. All of this was a good learning experience as I became more involved in flight hardware design. Designing man rated flight equipment is not a simple process as the design must go through conception and analysis, prototyping, testing and a worst case analysis and then be brought into fabrication for production with return loops back to correct problems that arise along the way. This requires senior design experience as well as a good working knowledge of the quality requirements for man rated equipment. The Applied Research Branch had already brought into production a flight qualified 450VA Inverter for use on the Saturn program. The Inverter produced three phase 115 volt 400Hz power for various vehicle loads from a 28 VDC bus. It was mounted in the Saturn (IU) Instrument Unit ring and was flown on SA(5)-SA(7). The Branch in earlier years had been upgrading flight rotary inverters (DC motor-generator set) dating from the Redstone vehicle but arcing brushes in a DC motor-generator set was not suitable for the vacuum of space and a new technology was essential.

Our Division Chief James (Jim) Taylor (dec) and Branch Chief Bill Kreider (dec) and the engineers knew the risks and responsibility involved in designing and building flight hardware and taking the “heat” and blame when there was a failure. Elbern Lentz (dec) told me the story of the onboard rotary inverter getting the blame for the failure of the Juno II (AM-16) launch vehicle launched on July 16, 1959 that failed with a loss of power to the control system and had to be destroyed by Range Safety. The failure was blamed on two top-hat diodes being shorted out on a printed circuit board inside the inverter. I was shown a photograph of the shorted diodes. The launch attempt created one of the most spectacular failures ever seen at Cape Canaveral. https://www.youtube.com/watch?v=61A6cpSXsnA contains a video of the failed Juno II launch. After the vehicle failure and explosion occurred high level managers rarely seen before showed up in the Division and Branch wanting to know how and why the failure occurred and wanted the problem analyzed quickly and a fix implemented. An investigation found that a short circuit had occurred between the two top-hat diodes in the rotary inverter voltage regulator. Elbern Lentz (dec) told me there was also damage from the explosion and it was difficult to determine if the explosion and impact shorted the diodes or if they shorted at the time of launch. The shorted diodes caused the power to the guidance system to be shutoff, resulting in full gimbal and vehicle loss. Future circuit boards were conformal coated to reduce the chances of it happening again. The loss of a vehicle did not stop the program during those challenging times with the Russian launch competition. These were the years of experimental rocketry where there would be one or two successive failures and then a successful launch. Another Juno II was soon prepared for launch, confirmed that it did not have the same problem and was launched successfully and the Juno II program continued. The problems and characteristics of the rotary inverter forced the development of a new technology Solid State Inverter used in the Saturn program. The Saturn programs stated use for the 450VA inverter follows and were taken (2 excerpts) from the following NASATRS. NASA Technical Reports Server (NTRS) 19650012954: Saturn I electrical power and systems integration sa-5 through sa-7. This document is accessible on the internet and included in the reference documents. The inverter was physically located in flight configuration in the Saturn (IU) Instrument Unit shown in the following diagram taken from the Failure Information Notebook. This document is accessible on the internet and included in the reference documents.

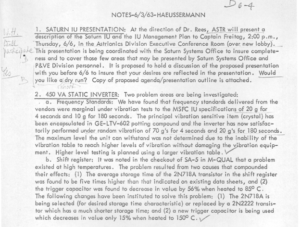

The 450VA inverter design required these large power transistors to chop up the 28 VDC current and transform the power into 115 volt three phase 400Hz output using additive transformers timed by a frequency standard oscillator feeding into a shift register to control sequencing of the transformers. The assembly used all discrete devices as integrated circuits were research devices. The transformers were controlled using magnetic amplifiers switching in an additive pattern to generate a three phase quasi sinusoid wave at 115 volts at 400Hz. There were frequency standard and shift register technical problems that arose in the inverter that were detailed in a weekly note that was sent to the desk of Dr. Haeussermann on 6/3/1963 and to the desk of Dr. Wernher von Braun on 6/4/1963 and shown below. These were copied from his personal weekly notes found on the MSFC History Office page. The document is accessible on the internet and included in the reference documents

- ELECTRICAL POWER

The electrical power system of Saturn SA-5 through SA-7 consists of 28-volt batteries, 5 types of power supplies, and 450 VA static inverters. One pair of the batteries is located in unit 12 of the S-I stage and the other pair is located in the Instrument Unit. Each battery supplies an independent bus.

Another type of electrical power equipment, although not furnished by the Electrical Systems Integration Branch, is the 450 VA static inverter that has an input of 28 V d.c. and an output of 3 phase 115 V 400 Hz. Four inverters are used on SA-5 and SA-6 (3 in the Instrument Unit and 1 in the S-I stage), while only three are used on SA-7 (2 in the Instrument Unit and 1 in the S-I stage) .

There were significant problems that surfaced in the inverter design during prototyping and testing in attempting to use available power semiconductors for the solid state technology design. The design required robust high current transistors to do the power switching. The available germanium power transistors were prone to failure due to being less capable of withstanding voltage spikes and high thermal dissipation. The failures and screening tests were showing as high as a 50% failure rate for these transistors. It was known that the voltage capability and thermal dissipation of silicon transistors were greater but further device development and qualification testing was required to have them approved as class “S” space grade parts. The development of the Westinghouse series 2N1509-2N2109 family of “Rock Top” silicon transistor with the ”concentric annuli” internal construction shown in the following photograph on the left became a breakthrough device after passing the required tests for space flight qualification. The photograph on the right is of the packaged device taken from my personal collection. (Transistor, NPN, Max voltage; 50V, Max current: 30Amp. Dissipation: 250 Watt. Package: 1/2-20 UNF, stud flag type terminals. P/N: 2N2109. Operating temperature: -65 to 175 Deg C. Note Fused silicon

The 450VA inverter design required these large power transistors to chop up the 28 VDC current and transform the power into 115 volt three phase 400Hz output using additive transformers timed by a frequency standard oscillator feeding into a shift register to control sequencing of the transformers. The assembly used all discrete devices as integrated circuits were research devices. The transformers were controlled using magnetic amplifiers switching in an additive pattern to generate a three phase quasi sinusoid wave at 115 volts at 400Hz. There were frequency standard and shift register technical problems that arose in the inverter that were detailed in a weekly note that was sent to the desk of Dr. Haeussermann on 6/3/1963 and to the desk of Dr. Wernher von Braun on 6/4/1963 and shown below. These were copied from his personal weekly notes found on the MSFC History Office page. The document is accessible on the internet and included in the reference documents.

It was essential to have a competent electronics engineer lead in performing a “worst case analysis” on the entire electrical and electronics configuration of the inverter. The Applied Research Branch was fortunate to have that capability available in John M. Gould. He had been drafted into the Army after graduating Summa Cum Laude in Electrical Engineering from a NYC technical university and had been stationed at Redstone Arsenal working on Squirrel Hill. He was a brilliant, experienced, soft spoken, pipe smoking, engineer with a thorough knowledge of electrical and electronics theory to perform a total systems analysis on the 450VA Saturn inverter and other inverter designs in development. His office was a maze of stacks of paper 2 feet tall placed on his large GS-15 desk with a small open area in front of his chair to work with a nearby ashtray. He knew where every sheet of paper was and what was on them if needed and he could go down the stack and with draw them out rapidly. We referred to it as John’s vertical filing system. His office always presented a challenge during safety inspections. The development of a 250VA Static Inverter was ongoing work as a need had been identified for a lower power solid state inverter that was man rated for flight. A report from a contract for the Development of Reliability Methodology for Systems Engineering on the design is included in the reference documents. The document is accessible on the internet. John and other knowledgeable analysis in the Division who supported the 450VA worst case analysis established that the design was acceptable to proceed into flight production. A contract with the Bendix Corporation was put in place to fabricate inverters for the Saturn program. An enormous amount of work both hardware and documentation went into getting a piece of equipment acceptable to be installed on the man rated Saturn vehicle. Every step from design, development, development testing, parts used, fabrication, acceptance testing and the “build paper” must be documented and have quality traceability, “back to the ore it was made of” someone once said. This was to ensure that “no stone has been left unturned”. This principle and implementation even though very costly was practiced by the managers, engineers, technicians and support personnel to deliver the reliable vehicles necessary for the Saturn program. The result was 13 successful Saturn 5 launches over the course of the program. The MSFC Quality organization was always involved in any component or piece of equipment to be installed on the flight vehicle. I think the majority of those who worked at MSFC who were involved in designing, testing or analyzing a man rated piece of equipment would have felt a burden of responsibility to get it right and make it work. There was enough spunk in the attitude of the engineers to believe it could be achieved and a successful moon landing and safe return would result. There was the engineering side of these individuals that thought in terms of calculations and hard data but there was another side involving human emotions that sent managers and engineers to their knees in prayer prior to a launch and during missions where failures, grave dangers and loss of life could have occurred. The Saturn program learned from its mistakes and made design changes and corrections when problems were found during testing or from failures. Unfortunately the Saturn program did not escape the painful loss of life and great personal sacrifices in making the program a great success in the end.

It was a memorable learning experience for me to work under the wings of these older master electrical engineers and technicians. Many of them had served in some branch of the military service and had received training in electronics. They demonstrated confidence in what they knew and had a “can do” attitude. If a technical problem arose one of them would come up with a solution and follow up with testing. NASA benefited greatly from all of the military experience that was brought into the agency. NASA as a new civilian agency was less rigorous than the military with protocol but at the same time demanded high quality and multiple redundancy in its man rated flight hardware.

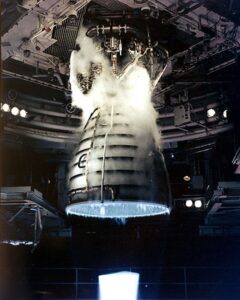

During the years the Saturn program was ongoing there was often an engine test firing at MSFC in one of the test stands. We would get an alert in the laboratory and would regularly ascend to the top of the “Pogo” tower adjacent to Building 4487. There was an observation deck on the top with a hand rail and a clear view of the Saturn IC Test Stand. The exhaust flames would first appear to the eye as the firing was initiated and then the earth would begin to shake as the firing vibration next reached the tower base and entire structure and then lastly the roaring sound waves would arrive at the ear and pound upon the chest. It was a visible, physical, and audible experience that was felt all over the body and is unforgettable.

During my first year at MSFC I also assisted engineers in the Instrumentation Branch under Tom Escue located in B-wing of the Astrionics Laboratory in the static and dynamic testing of Statham pressure transducers used throughout the Saturn boosters. Ray Holder was the lead engineer with Hugh McCain the technician and two IBM contractors doing the testing. The transducers provided line pressure data on the many fluid lines that laced the inside wall and were required to monitor booster operation during tests and in flight. This was my first experience in the Environmental Testing Branch vibration laboratory located on the first floor of the “Pogo” tower. I had a family relative John Frazier (dec) who worked in the thermal-vacuum testing area also located on the first floor. The “Pogo” tower itself was a drop test used to test low-G gravity effects on test articles. The vibration laboratory was operated by Ruben Miller and Dave Light. The Transducer under test was mounted on an electrodynamics “shake table” that was programmed to follow the Saturn 5 launch and ascent vibration profile. The transducer was monitored electronically during the test and it was an extremely noisy and brutal test as the Saturn 5 went through phases of high levels of vibration. Ruben Miller considered it a successful test if it the transducer failed where as we wanted the transducer to pass the test. Accurate vibration testing for a transducer or a flight packaged inverter with many electronic components inside was vital to insure the high reliability required of the Saturn 5 vehicle. I was taken on a tour of the Saturn IC Test Stand by Ray Holder from the Instrumentation Branch. Often boosters were seen being hoisted by the massive overhead crane used to place them or remove them from the test stand. Ascending the 400 foot tall test stand by elevator and exiting to walk along the high catwalks at the top of this massive structure at MSFC brought into scale the size and power of the Saturn stages required to deliver the Apollo crew to the surface of the moon and return them safely back to earth. Driving into MSFC each day to work would present a view of the Dynamic Test Stand directly ahead as a constant reminder of the height of a fully stacked Saturn 5 and the magnitude and scope of the vehicle being developed at MSFC that must not fail to make the program a success.

Saturn launches occurring during work hours were viewed on a rack mounted black and white TV monitor with an added tuner located in a laboratory down the hall in C-wing using a roof mounted antenna tuned to a local Huntsville, AL television station. The Saturn vehicle launches were serious business as we all felt a responsibility for it being a success or failure but a sigh of relief and joy was reflected as the vehicle ascended and it was confirmed that orbit had been reached. The Saturn program was a special program that leaves you with those one-of-a-kind memories in many different ways. You can’t help but be grateful that you were fortunate enough to be a part of the program. Over the years I was fortunate to meet and shake hands with Neil Armstrong (dec), Buzz Aldrin, Gene Cernan (dec), Flight Director Gene Kranz, Owen Garriott (dec), and other astronauts who visited MSFC adding to my good memories of the program. But it was the individuals with unheralded names working in the legions of technicians, engineers, draftsmen, mathematicians, scientists, accountants, clerks, secretaries and other support workers requiring long self sacrificing hours in laboratories, offices, quality control facilities, manufacturing, test stands, computation facilities, transportation centers, launch and mission control facilities and other sites giving of themselves to bring the Saturn Apollo program to a successful completion with U.S. Astronauts walking on and exploring the Good Earth’s moon and returning safely back to earth bearing a report on our nearest celestial body. It was truly an amazing and historic event that offered the opportunity to work on the program and be a tiny part of its engineering.

I will include a closing note on Dr. Wernher von Braun (dec). As a young engineer at MSFC I held Dr. von Braun in awe. I first remembered seeing him in Building 4200 basement cafeteria eating with the other Germans and with some Americans and going into the barber shop to get his hair cut. I would occasionally see him driving around MSFC in his large Mercedes. In 1969 after the successful Saturn Apollo 11 moon landing and return occurred and new Saturn work was ongoing with the follow-on OWS/SKYLAB program he came down to our C-160 laboratory on a visit. The C-160 laboratory was given a new and different task assignment by Bill Kreider our Branch Chief to support a bio-medical electronics development task out of (JSC) Johnson Space Center. Bobby Bynum(dec), a controls system engineer in the Astrionics Laboratory along with the Applied Research Branch were tasked to develop a plethysmograph that was used on an exercise bicycle being designed at MSFC for the astronauts use on-orbit. The device was used to sense and measure the heart rate of the OWS/SKYLAB exercising astronauts and provide data to a load controller. A joint MSFC-JSC meeting was arranged for Dr. Charles Berry, the Astronauts Physician, from JSC. Dr. Joe Randall (dec) was the Astrionics Laboratory representative during the meeting. The work was to demonstrate how MSFC could support JSC in developing bio-medical electronics. All of these men came to the Astrionics Laboratory for the meeting and came down to our C-160 laboratory. It was a significant change from our earlier tasks of designing power supplies and inverters. Since starting the bio-medical task, I had fabricated with Bill Boshers, a mechanical designer, a device that slipped over the finger to detect the blood flow to the finger and display it as a string of electronic pulses on a Tektronix 545 oscilloscope. The device contained a light source and a photocell sensor with connecting wires. The device sensed the heart rate of the astronaut and was used to limit or control the electronic load that was a part of the exercise bicycle foot pedal assembly. It was such a thrill for me just to shake Dr. von Braun’s hand but he wanted me to explain the details of what we were doing technically. I was asked to place the device on his finger and discuss what we were doing and how it worked. As I did this I remember looking at his face, head, hair and temples with thoughts of the vastness of this man’s knowledge and experience as the world’s leader in spaceflight overwhelmed me. Dr. von Braun (dec) was getting older but he still had that German rocket scientist aura about him that drew respect and yet he had that deep engineering interest and the gifted capability to make a young engineer feel like they were an important part of the overall space program. He was patient and a good listener and took his time to ask questions. Dr. Charles Berry the Astronaut Physician was along and this joint MSFC-JSC work was new and significant as MSFC and JSC did not have a history of the best working relations being viewed as competitors. Dr. von Braun (dec) made a lasting impression on me and it was said he created this feeling all the way down to the custodians in the facilities. I know the encounter motivated me in my career and it was a great loss in his transfer to NASA headquarters to do NASA future program planning and that led to his decision to leave NASA and go to the Fairchild Corporation. Tom Keefe (dec) was an older engineer from Mississippi who was working in the C-160 laboratory on an automatic blood pressure cuff as part of the bio-medical electronics task and he demonstrated that device on Dr. von Braun.

As the Saturn Apollo program was winding down with the last of six successful moon landings and returns and the successful OWS/SKYLAB missions there were major reorganization changes that began to take place with (RIF’s) Reductions in Force occurring. Amy and I were married in 1968, the year that was saved by the Saturn 5 Apollo 8 mission of orbiting the moon at Christmas time with the astronaut crew of Frank Borman, Jim Lovell and William Anders delivering a “for all of the people on earth message” reading of the Biblical record of the creation while the people on earth listened. Andy was a Saturn 5 Apollo 11 launch month baby born in July of 1969 and Stephanie was a Saturn 5 Apollo 15 launch month baby born in July of 1971 joining our dog Thor to add to our growing family. Apollo 15 saw the first use of the (LRV) Lunar Roving Vehicle. The LRV was developed by a task team under the direction of Dr. von Braun (dec). There was a development model that was brought to Building 4487 for tests by the Controls Division that was driven outside between A and B wings. I remember looking at the LRV and thinking about all of the amazing developments that came about as a result of the Saturn Apollo program but we knew the program was nearing its completion. The rumors of RIF’s and reorganizations and the reality of them as they began to happen was unsettling and many employees were affected. Our Division contained quite a few older veterans who choose to retire. That reduced the need to RIF Division employees and I was fortunate to not be affected by the RIF’s. I found the best way to stay sane during those troubled times was to hunker down and keep the faith and stay busy working on whatever project work flowed down to the Branch or fill in time with make work that would improve my engineering skills or improve the capability of the laboratory. It was best to believe that MSFC had a solid future and that the programs that were already started and in (PD) Preliminary Development would continue with unmanned or manned space exploration. We were reorganized into a new Branch with John Gould (dec) as the Branch Chief and Harrison Garrett (dec) as Division Chief with a new task of Microelectronics Computer Aided Design and Test that would produce new design software and hardware products we could not have imagined. A few years later we were reorganized into the Parts Branch under Dr. Alvin Holliday (dec) and a few years later merged into the Electrical Systems Division under Jim Miller. Each one of the organizational changes brought new and different tasks and types of work. The benefits from the engineering foundation learned in the C-160 laboratory was always an asset as the work tasks and type changed over the years. I was redirected by the Electrical Systems Division reorganization under Jim Miller into tasks as a flight solar cell, flight solar array and flight battery specialist going full circle back to my early years in electrical power conversion. A new engineer is now often given a cubicle and a personal computer and a remote or if any laboratory and in so doing is missing much of the engineering basic training and the fun of learning from an extended time spent in a good hands-on laboratory. Those were good and exciting years at MSFC when the Saturn Apollo program was in full swing but even with the following downs and ups there would be many other good years to come and good programs to work. The (HST) Hubble Space Telescope, the (STS) Space Transportation System (Space Shuttle), the (ISS) International Space Station, Chandra, (TSS) Tethered Satellite System, Gravity Probe-B and other small space flight programs and tasks that held MSFC together as a strong Space Flight Center.

Teddy (Ted) M. Edge, 4/8/2019

REFERENCES:

- https://archive.org/stream/NASA_NTRS_Archive_19650012954/NASA_NTRS_Archive_19650012954_djvu.txt

- https://archive.org/stream/NASA_NTRS_Archive_19650012954/NASA_NTRS_Archive_19650012954_djvu.txt

- https://history.msfc.nasa.gov/vonbraun/documents/VB_WN_196306.pdf

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660018753.pdf

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660018753.pdf

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660018753.pdf

QUOTES:

“One good test is worth a thousand expert opinions” – Dr. Wernher von Braun

“That’s one small step for man, one giant leap for mankind.” – Astronaut Neil Armstrong

“I didn’t feel like a giant, I felt very, very small” – Astronaut Neil Armstrong

“It’s a great thing for a man to walk on the moon. But it’s a greater thing for God to walk on the earth.” – Astronaut Neil Armstrong

“This has been far more than three men on a mission to the Moon; more still than the efforts of a government and industry team; more; than the efforts of one nation. We feel this stands as a symbol of the insatiable curiosity of all mankind to explore the unknown” – Astronaut Neil Armstrong

“I am now, truly alone, and absolutely isolated from any known life. I am it. If a count were taken, the score would be three billion plus two over on the other side of the moon, and one plus God knows what on this side.” – Astronaut Michael Collins

“Anyone who sits on top of the largest hydrogen-oxygen fueled system in the world; knowing they’re going to light the bottom, and doesn’t get a little worried, does not fully understand the situation.” – Astronaut John Young

“As we got further and further away, it [the Earth] diminished in size. Finally, it shrank to the size of a marble, the most beautiful you can imagine, that beautiful, warm, living object looked so fragile, so delicate, that if you touched it with a finger it would crumble and fall apart. Seeing this has to change a man.” – Astronaut James B. Irwin

“As an astronaut, I understand the ecliptic; how the Sun generates energy; and even how to navigate using the stars. Yet the breathtaking sight of a starlit night brings tears, at the mere thought of our improbable existence.” – Astronaut Doug Wheelock

“When I first looked back at the Earth, standing on the Moon, I cried” – Astronaut Alan Shepard

“Memory is the treasure house of the mind wherein the monuments thereof are kept and preserved.” – Thomas Fuller