by Jim Splawn

Jim Splawn – – NASA Neutral Buoyancy Simulation

I was born in Kentucky, raised in Tennessee, educated in Georgia at Georgia Tech, graduated in 1957 as an Industrial Engineer, employed in private industry for 4-years.

My NASA career began on June 1, 1961 when NASA / Marshall Space Flight Center (MSFC) was 11-months old. I came as a fresh young energetic engineer ready to team up with a group of Germans of whom I had no knowledge, to develop rockets for the peaceful exploration of space, and place man on the Moon in the process.

My first assignment was in the Fabrication Laboratory (later to become Manufacturing Engineering Lab) as a production planner 1) for the Saturn-1 rockets, and 2) for the Saturn-5 rockets, to be used by the Test Lab for design and performance verification testing. This was a very comfortable environment that meshed nicely with my private industry experience. My assignments in the ME Lab eventually led to the Lab’s Executive Staff.

Along with the assignments given to each laboratory, MSFC management encouraged and provided the freedom for employees to think “outside the box” on items that might have applications in future missions. Employees responded to this micromanagement environment. We had no definitive mold that shaped us for placing man in space …. we were all learning! An attractive environment!

The development of what would become the Neutral Buoyancy System (NBS) is an out-growth of this environment.

Background

In the ME Lab, there were five of us that would meet most days at lunch time, open our little brown sack, sit down around the table and just talk. The little brown bags recorded our ideas and dreams. By the mid-60’s, we were convinced we were really going to land man on the moon! So, our next logical question was, what will we do then? What will our missions be? After discussions, we agreed man would work on- orbit, but we could not define the tasks. But one thing was basic, man must be trained to function in weightlessness, 0-G.

Multiple devices were defined and evaluated with experimental hardware (ie: off-setting springs, epoxy self-leveling floor with air-bearing pads supporting numerous hardware devices, counter-balancing devices, etc.). All had significant shortcomings.

Our small group would dream and debate. We’d eat our sandwiches and talk about the kids, family events, etc. One day, someone stated their big event had been at the pool with his family and concluded by asking “Have you ever watched your wife swim underwater”? We pumped our fist in the air and said “You betcha.” He said, “Come on guys, be serious …. how did her hair react?” Then he responded with hand-waving motions, “It just floats!”

Silence! But you could tell heavy thinking was underway. We took that comment and went to work …. Neutral Buoyancy System (NBS) had just been born!

The basic five guys that developed the evolving vision was Charlie Cooper, Charlie Torstenson, Don Neville, Charlie Stocks, and myself. A good skill-mix of engineers and technicians existed within the group.

Our assessment for crewmen and mission specialists training internally to the on-orbit spacecraft for the conducting of experiments and equipment repairs would be somewhat straight-forward due to the operational shirt-sleeve environment. In contrast, the external habitat on-orbit environment was a different challenge for training that needed to be addressed. Consequently, we began the pursuit of requirements and equipment for EVA (External Vehicle Activity). “Manned space” would happen! And so would EVA’s.

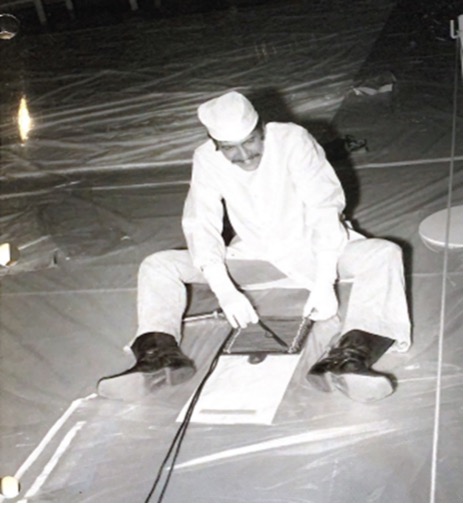

As we began to work the details, the principles we followed were: when a body or mass neither floats nor sinks when submerged in water, a condition achieved by a non-interfering low-profile harness of distributed weights strategically located on that body or mass, the mass becomes ‘weightless’ or neutrally buoyant – – it’s suspended! If that body is contained in a pressure suit, now weightless, the crewman becomes dependent on maneuvering assistance devices (handrails) and/or station-keeping devices (body or foot restraints) to accomplish tasks at strategic work stations. The tools used on-orbit also need to be neutrally buoyant for training purposes without encumbering the tool’s normal function. An umbilical tied back to the habitat would provide air for breathing, sensors for medical evaluation and communications. Safety divers in scuba gear would meet safety requirements for NBS operations.

The fundamental ‘needs’ for such an endeavor mounted quickly: a body of water, pressure suits, scuba equipment and divers, monitoring instrumentation, a control room, support from MSFC’s Medical Center, safety procedures, operational procedures, fabrication shop support to building mock-ups for underwater usage, etc.

Early Days

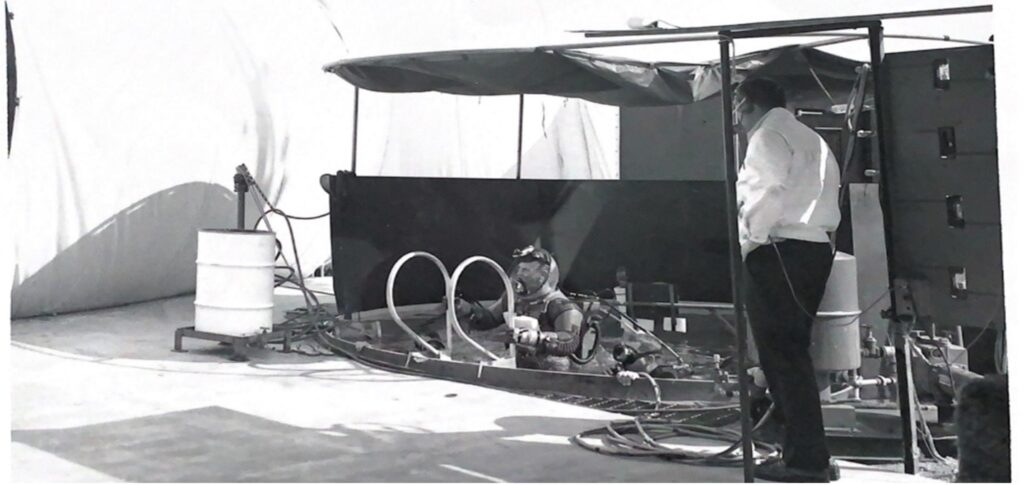

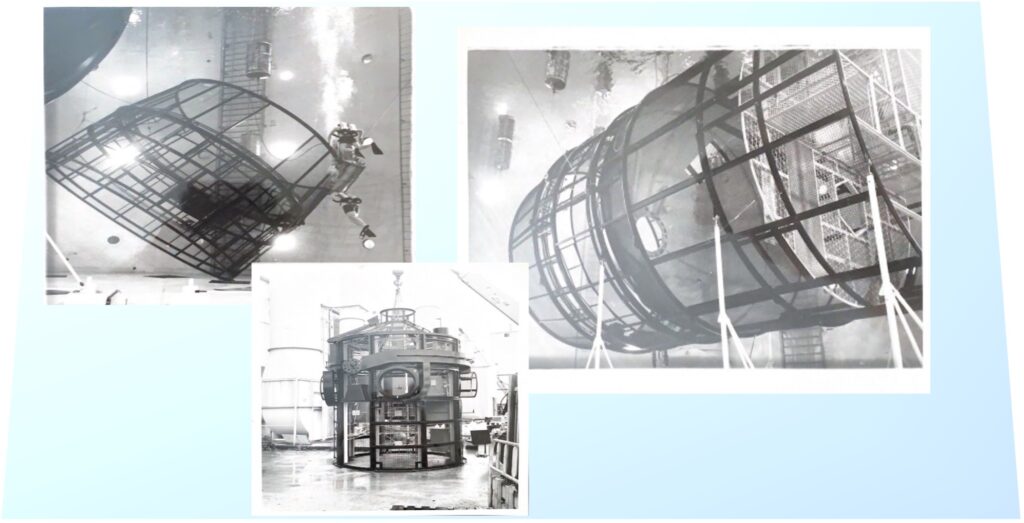

In 1965 our first ‘tank’ was a 10-ft diameter explosive-forming pit, used for forming propellant tank closure domes, that had been abandoned by the ME Lab (Figure 1). A water filtration system was purchased from Sears Roebuck and four Arrowhead high-altitude flying/pressure suits were acquired from Navy salvage. A makeshift tent above was of little help. Charlie Cooper was our primary test subject. Our experimental base began with very remedial tasks. It was a meager start, but our dream was becoming a reality. We were still performing our normal job duties, but used our lunch-time and after-hours to evolve our future vision. Nothing had been formally announced yet.

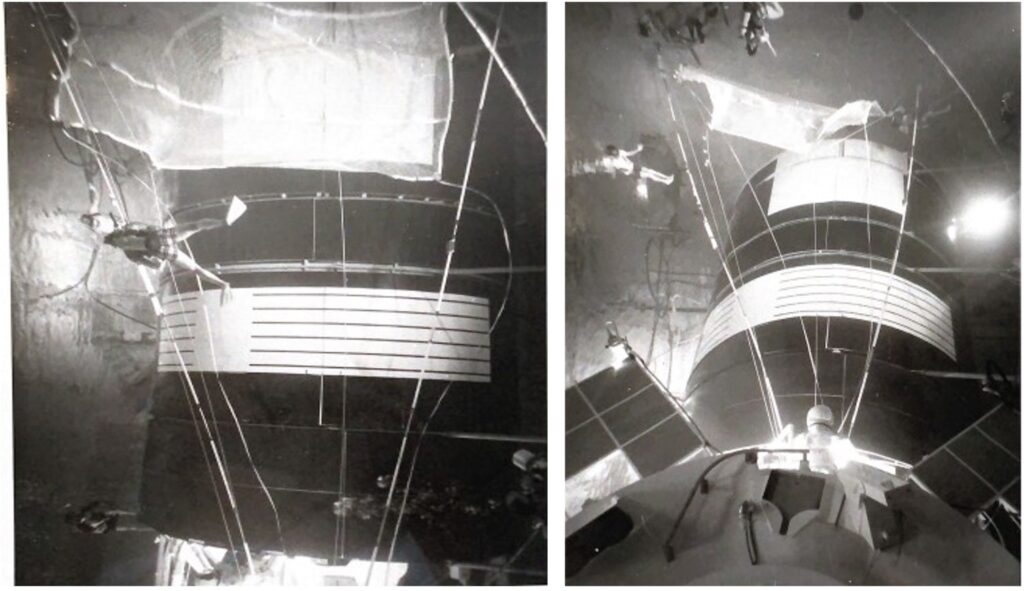

Our second tank began with an inner stage section of the Saturn V vehicle from the salvage yard which became the side walls surrounding the tank. Previously used as a test article, the 33-ft diameter, with a 15-ft deep pool below worked extremely well (Figure 2). A tent enclosure completed our new work space. Thanks to our electronic technicians, underwater TV, and a voice communication system were incorporated, as well as some task hardware furnished by the shops. We could now work year-round with training development while providing protection for our electronic equipment.

By late 1966, the part-time workload for our small volunteer staff was becoming more complex. Recognizing the potential of this activity, the ME Lab Director announced an organizational change: Cooper, Torstenson, Neville, Stocks and Splawn, as Manager, were assigned as full-time for these space simulation activities.

In May 1967, our NBS staff felt sufficient progress had been made to the level where senior MSFC management should become more aware of our capabilities. This included Dr. von Braun and his laboratory directors. Accordingly, Dr. von Braun was invited to witness a test; he accepted immediately. Dr von Braun was impressed with what he saw, gracious in his comments, and encouraged us to continue with haste. Even with the rather crude appearance of the facility conditions, he gave us a “thumbs up … keep going” response.

In this timeframe, JSC in Houston acknowledged our months-old request for pressure suits and provided six Gemini suits of varying sizes for our NBS usage. Don Neville, our supervisor for the pressure suits and associated equipment, visited JSC for specific training on care and maintenance of the suits.

In Nov 1967, Dr von Braun requested that he become the test subject in an Arrowhead suit and that he would bring a guest. On test day, we were surprised when “Guest” Astronaut Gordon Cooper (Figure 3) arrived with Dr. von Braun. If the MSFC Director invites you to witness his becoming a test subject in a pressure suit (Dr von Braun’s first time to be in a pressure suit) in a new weightless simulation scheme, it must be something special and have strong potential! Dr von Braun was a super test subject, chatting continuously with the test director and safety divers, asking questions, and summarizing his feelings and sensations of performing tasks in a pressure suit in weightless conditions

The after-test de-brief exhibited confidence and encouragement in what he had just experienced. Astronaut Cooper was favorably impressed and commented that Dr. von Braun would make a good Astronaut.

Dr. von Braun’s big question was: “What’s needed to go forward?”

Obviously, we had just witnessed a “grand slam homerun”!

From this point on, things began to happen really fast. In fact, they exploded! Dr. von Braun invited several Astronauts, Congressmen, and NASA Headquarters executives to witness a NBS test.

The “Big Tank”

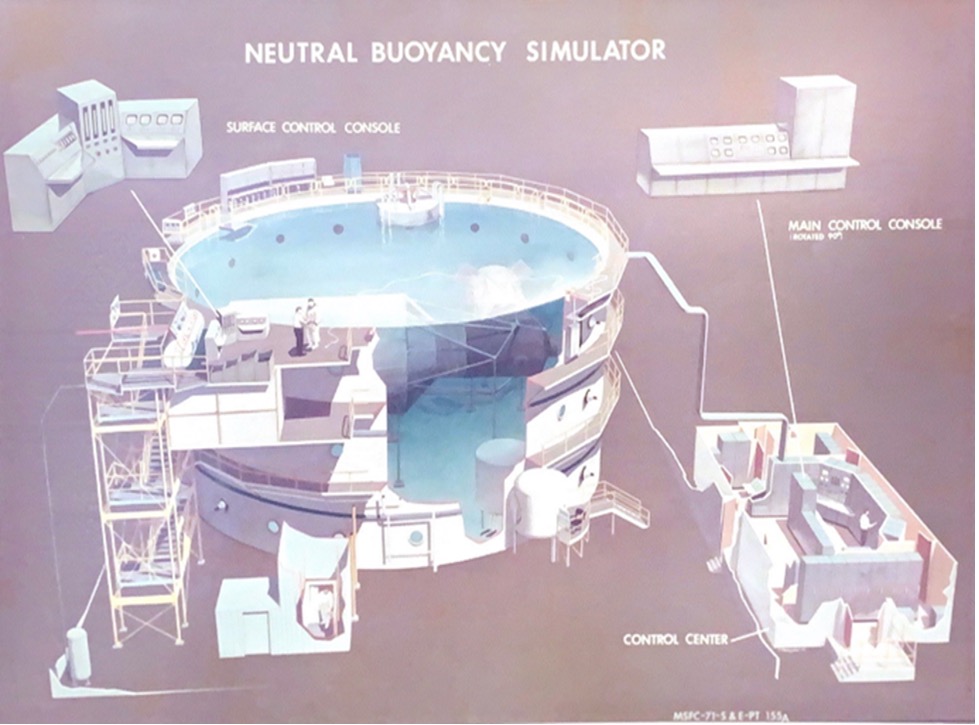

At the Center level, plans for a new facility (nick-named as the “Big Tank”) was initiated, and a formal MSFC organization was established. Dr. von Braun made the decision to build the large 75-foot diameter x 40-ft deep tank, containing 1.3 million gallons, as an in-house design-and-build project. A long-range plan was to train the flight crews for the Skylab program.

Dr. von Braun sent word to us that he wanted a “first-class facility …. no junk”. All systems in this facility had to be certified to meet “man-rated” training requirements.

The Big Tank was declared an “in-house design and build” by Dr. von Braun. The Test Lab took the lead with its experienced crews of welders and skilled steel workers. They were fantastic!! Construction was started in June 1967; completed in May 1968. This construction caused a lot of ‘talk’ around MSFC.

The formal organization structured consisted as follows:

Jim Splawn, Branch Chief

Gail Moss, Secretary

Charlie Cooper, Simulation Engineering Operations Supervisor, Primary Test Subject

Elmer Bizarth, Test Conductor

Bill Cruse & Charlie Torstenson, Instrumentation Supervisors

Don Neville, Pressure Suit Supervisor

Sam McClendon, Hardware

Pete Nevins, Tech Writer

Dr James Spraul & Dr Tulio Figurola, Medical Team, MSFC Medical Center

Ernie Hardin, Underwater Photo & TV, MSFC Photo Lab

Ten (10) U S Navy SEAL / Divers, (On board in 1971; 2-year temporary assignment)

(Note: The NBS staffing was basically hand-picked from the volunteers that had worked diligently with us to provide a cross-trained basic staff that understood the mission that we had been assigned. Ultimately, our total headcount was approximately 45.)

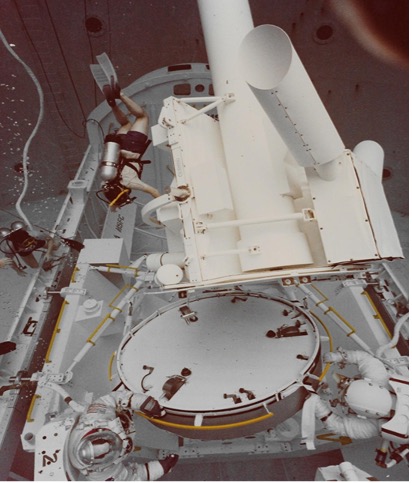

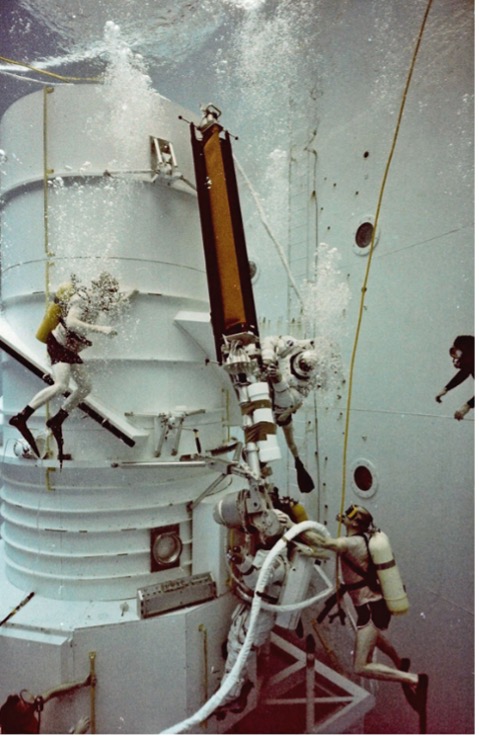

The control room contained a full complement of high-quality broadcast-worthy equipment and space accommodations for the test director and his full complement of staff for safe and meaningful test operations. Underwater systems included both hard mounted pan-and-tilt and portable TV cameras, audio for safety divers to monitor all communications between control room and test subject, electrical power for experiments, supplementary lighting via selected port windows, mounting stanchions for large test hardware, a safety diving bell at the 35-ft level as a rescue haven, and an air-lock through the tank wall permitting a doctor and medical equipment to enter the diving bell. Three exterior platforms circled the tank for viewing test activities via 48 each 2-ft diameter port windows. The building metal roof panels were replaced with fiberglass panels to increase the underwater light levels. A passenger and small equipment elevator served the top deck. A two-chamber recompression chamber was positioned on the top deck for the purpose of treating any test subject or diver emergency. A “hot-line” to the medical center was located on both the top deck and the control room. All systems in this facility had to be certified to meet man-rated training requirements. The Big Tank construction was completed in May 1968.

In early Fall 1968 the NBS became fully operational.

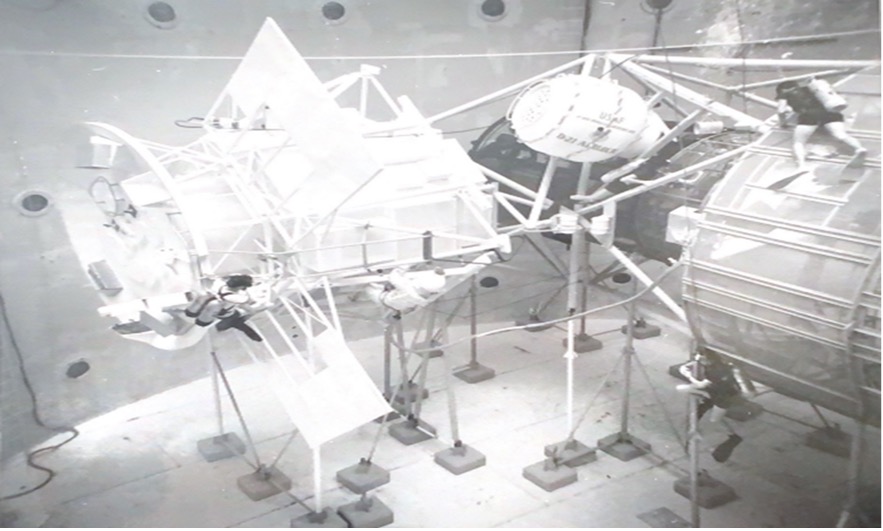

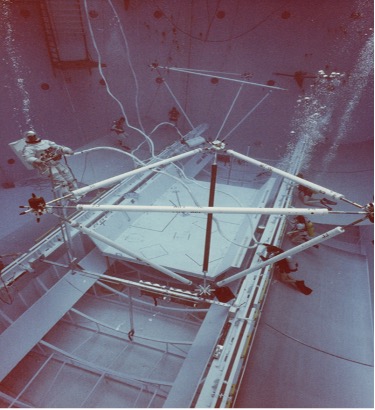

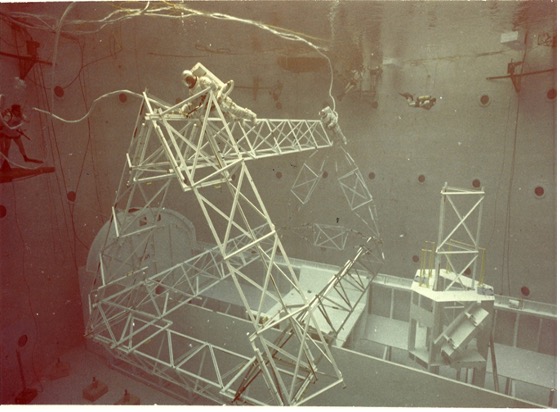

In parallel with tank construction, the SKYLAB hardware was being fabricated by ME Lab for under-water usage (Figure 5). This hardware was required to be accurate in dimension and function, free of any sharp edges or snag points that could tear a pressure suit, exterior skin materials should be open mesh to permit natural daylight penetration for interior test operations, and light weight for diver’s ease of handling. For the S-IVB stage, only a partial top section was required but still of the 22-ft diameter. All other components of the Skylab cluster were to be full-scale. Again, we would be training the Astronauts for EVA (or “spacewalk”) operations.

It was obvious the operational procedures and safety procedures were requirements that must be documented. Since there was no manual of history to guide us, it was a tedious, time-consuming, trial/error, monster that had to be done. Particularly, when training the caliber of our test subjects.

From 1969 to 1972, two major activities were underway. First, the NBS was under construction and activation was urgent in preparation for training the Astronauts for their extended stays on-orbit, both internally and externally to the Skylab habitat. Second, the follow-on NASA program after the successful Lunar Landing was the Skylab program, basically conceived by MSFC. Simplistically stated, Skylab’s purpose was to serve as NASA’s first Space Station, and to define the impact of long-term exposure to weightlessness, if any, on the human body and its functions.

Many hundreds of hours in the NBS were spent in simulation tests: Skylab interior and exterior configuration upgrades, experiments maturing in hardware and operational upgrades, translation schemes and techniques for flight crew and materials handling, and fine-tuning of the multiple workstations.

The ultimate objective was to have a workable, productive, efficient space station for the 15 Astronauts that would be training for mission success. There is strength in multiple test subjects that captures varied backgrounds, skill levels, dexterity teamwork, etc.

Basically, the routine followed by our NBS test crew was fundamental within the NASA: design, build, test, modify based on results, test, modify, test, modify, (etc.) until test results are acceptable.

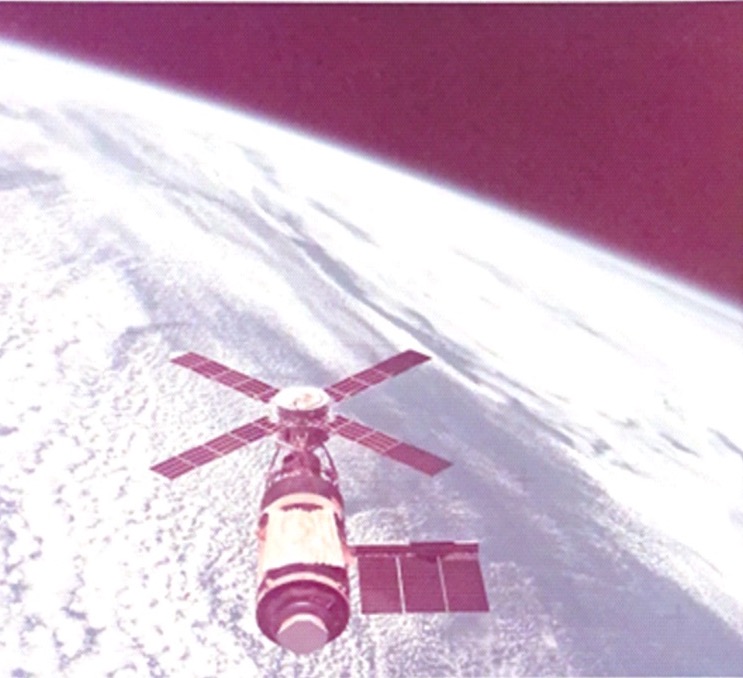

The Skylab cluster consisted of the S-IVB stage (known as Orbital Workshop (OWS and/or Habitat Stage), Multiple Docking Adapter (MDA), and Apollo Telescope Mount (ATM), deployed 90-degree.

Continuous testing by both NBS test subjects followed by Astronaut test subjects indicated a rotation scheme that was thorough, effective, and efficient. The NBS test subject(s) would evaluate the test-hardware and make changes dictated by the test results until a satisfactory final recommendation could be reached. After the best option was base-lined, the Astronaut would evaluate the NBS recommendation. Based on their likes/dislikes/judgement, additional testing may or may not be required. Over time, multiple Astronauts would provide their suggestions as they prepared for their flight. This routine of multiple evaluations by multiple test subjects builds integrity into the man/machine hardware for on-orbit success. This process can take weeks, but it is effective. Also, it is exciting to witness as the attention to details seeks perfection.

Looking toward the future, the International Space Station (ISS) was in design / build, so Skylab could contribute many significant “Lesson Learned” to the ISS mission, including hardware accessibility and function.

During the 1972 and early 1973 period, 15 Astronauts were trained, nine (9) prime crewmen and six (6) backup crewmen. They would fly their T-38’s from JSC, Houston, to MSFC air strip (about 45-minutes), test in NBS, then return flight back to Houston.

SL-1 Launch

The Skylab launch, designated SL-1, would occur on May 14, 1973. The SL-2 crew would be launched on May 15, for a 30-day stay-time, followed by SL-3 for 60-days, followed by SL-4 for 90-days. This 180-day on-orbit human exposure would build a significant data base for the forthcoming ISS.

Launch Day was perfect: clear sky, mild wind, warm temperature, all systems “go” … LAUNCH!! Our NBS team was monitoring and excited! But within minutes, an out-of-limits internal temperature indication signaled a problem. Then, practically no power was being received from the solar panel system. Rather quickly, it was confirmed we had a “stranded ship” on-orbit. Jubilation turned to concern. The SL-2 crew was placed ‘on-hold’ for an unknown timeframe.

Following the SL-1 launch, NASA in its entirety was on full alert to salvage Skylab; in particular, MSFC Huntsville, JSC Houston, and NASA Headquarters WDC.

As flight data unfolded, both MSFC and JSC were deeply concerned: MSFC from the standpoint of hardware integrity and repair solutions; JSC from the standpoint of flight crew comfort and safety; both centers for salvaging the Skylab mission.

At NBS, though we had no idea if-or-how we might assist, we quickly assessed that we needed to be ready for the unknown. Accordingly, we began a thorough evaluation of every system and subsystem to assure our readiness.

Analysis determined a weak or flawed area in the S-IVB external skin/heat shield had failed during ascent which explained the internal temperature rise. During this failure a metal strap had wrapped around the edge of one solar panel permitting its deployment to only 5-degrees (of 90-degrees planned). The solar panel on the opposing side of the vehicle had been torn away completely. Little did we know of the significant role the NBS would play in the days ahead.

Fortunately, the ATM solar panel system, located many feet forward of the failure area, had not been affected and deployed safely upon on-orbit command. A ground crew team at MSFC was successful in electronically diverting a portion of this power to the OWS … a lifesaver for Skylab (ie: food cooling, communications, experiments, working environment, etc.).

The Skylab basic structure was sound, but two key systems required immediate attention: Item 1) a scheme to protect a now-exposed exterior surface segment from the scorching sun rays; Item 2) free the remaining solar panel for the generation of solar power. These two major tasks would ultimately be worked simultaneously in the NBS.

Item 1) – Gold area: External micrometeoroid shielding torn away

Item 2) – White diagonal strip: Trapped solar panel

The two key systems received extensive NBS testing on multiple ideas in search of the “best and most efficient, yet simple, safe, and reliable” solution for the flight crew to accomplish. Following, in some detail, are the “Finals” that testing by both NBS test subjects and the flight crew(s) approved for flight.

For continuity purposes, the sequencing of “Save Skylab” will follow the tasks assigned to SL-2 and SL-3 crews.

Sun Shield (Temporary)

On-board sensors indicated the OWS was experiencing temperatures between 120/130℉ depending on daylight or night-time exposure. So, first priority was obviously to gain control of the temperature.

The task for correcting the internal temperature of the OWS was pursued by both Johnson Space Center (JSC) and MSFC. JSC Houston accepted the “temporary” sun shield option and MSFC accepted the “permanent” option.

For understanding purposes, the basic plans for determining the solutions to the problems that exist on Skylab will be addressed first, in general terms, followed by detailed actual performance by the crewmen on their flight.

(Approach): At Houston’s JSC, a scheme of utilizing an existing scientific airlock that provided a passage-way from internal OWS to the vacuum of space.

(Tools): An “umbrella/parasol” device would be developed and deployed providing a 19-ft x 21-ft coverage over the sun-exposed exterior surface. Since this device would be deployed from a shirt-sleeve environment inside the OWS, no EVA training was necessary for the flight crew.

Solar Panel

The second major task was to free and deploy the one remaining solar panel to meet the minimum power requirements for the full mission of Skylab.

A basic requirement: All materials and tools for repairs had to fit within the confining Command Module (CM) along with the flight crew and other carry-on items.

(Approach): The NBS staff would work with the ME Lab shops to manufacture a duplicate section of the solar panel that could be strategically mounted on the side of the underwater S-IVB. Skylab Engineering determined the most likely source of the strap entrapping the solar panel to be a 0.50” x 0.50” (“T” shaped) piece of aluminum-angle that served as an attach point for the large S-IVB skin panels. Knowing the material and cross-section of the entrapping strap (engineering drawings), a realistic duplicate would be fabricated and “wrapped” appropriately on the solar panel mockup in the tank.

(Tools): All candidate tools and ancillary equipment schemes from multiple sources, must be made neutrally buoyant, evaluated by the NBS team, and then by the flight crews.

(Operations): An immediate concern existed on accessibility. The entrapment area is located in an area where crewmen, it was thought, would NEVER be required to go. Thus, no handrails, no foot restraints, and no crewmen assist devices in the area, nor even getting to this specific area. That said, however, since the ATM, in its deployed position, is 90-degrees to the S-IVB cluster, a crewman may have a visual view of the entrapped solar panel.

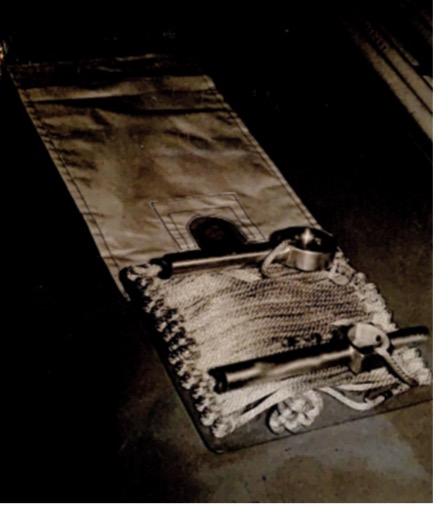

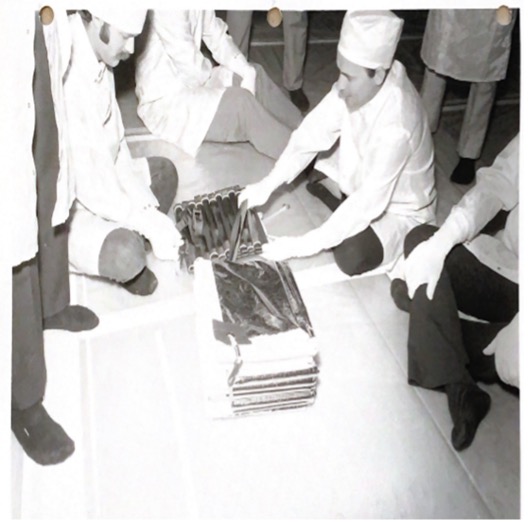

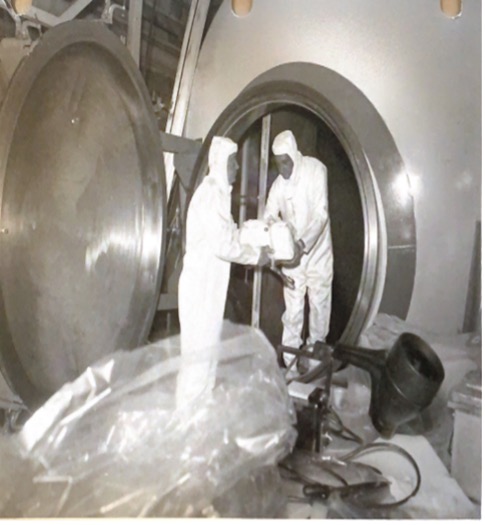

Once the selection for the final schemes for salvaging Skylab was approved, packaging and shipping began. One of our Navy SEALS had experience in parachute rigging so his skill was used for packing the sun shade and deployment ropes into a special design deployment container. For space-saving in the Command Module, the sun shade system was processed through a vacuum chamber, resulting in a package measuring 14” x 14” x 8”. Twenty-two (22) 5-ft poles were bundled, tools were packaged, ready for flight to KSC on May 24. A NBS representative accompanied the total hardware package, weighing 128-lbs, to witness the storage process in the Command Module.

SL-2 Launch

The 10-days preceding launch of the SL-2 crew was a whirlwind! Many, many people with varied skills, both NASA and Contractors, had sacrificed beyond belief. Families brought food, a change of clothes, and cots/blankets to their loved ones. Many saw the sunrise and sunset for several continuous days. Commitment was totally demonstrated!!

(An explanation: When the flight crews exit the habitat for an EVA, they are always identified only as EV-1, EV-2, EV-3, etc.)

On May 25, 1973 the launch of Pete Conrad, Joe Kerwin, and Paul Weitz left the launch pad riding on the prayers and good wishes of thousands of co-workers that had given their absolute best efforts to save Skylab for its full mission. The count-down was smooth; the launch was perfect. A good omen! As they approached the Skylab cluster, they confirmed their visuals matched very closely with the description and hardware on which they had trained for the last nine (9) days.

The crew did a fly-around, snapped photos, and reported Skylab structure looked good except for the two shortcomings that had previously, and accurately, been identified. Next came docking at the Multiple Docking Adapter (MDA) and entry into Skylab. They disrobed from their space suite and began activation of their new temporary home.

The emergency repairs for the SL-2 crew were two-fold: 1) deploy the “umbrella/parasol” to control the temperature, and 2) free the trapped solar panel to provide power …. Both critical issues!

On-board sensors indicated the OWS was experiencing temperatures between 120/130℉ depending on daylight or night-time exposures which occur every 90-minutes. So, first priority was obviously to gain control of the environment.

Sun Shield (Temporary)

The crew activated the penetration through the OWS wall via the scientific airlock. The parasol deployed nicely through the airlock with no problem. Upon command the rib structure sprang open leaving few wrinkles in the fabric; the temperature responded as expected, settling out in the mid-to-high 90’s. Success!! Skylab was now habitable for the 30-day mission as far as temperature was concerned …. temperature not desired, but acceptable. Action item 1) complete! Well done JSC!

Note 1: Control of the temperature was critical for refrigeration (a 30-day food supply for three crewmen); medical supplies; temperature critical experiments; etc.

Note 2: Following are the detailed processes actually used on-orbit by the crewmen.

Solar Panel

As expected, and as experienced (thanks to the shirt-sleeve environment in the habitat) the temperature control task was fairly straight forward. The remaining task to free the trapped solar panel was “risky and sporty” in the words of the crew during training. Teamwork and patience paid a huge dividend!

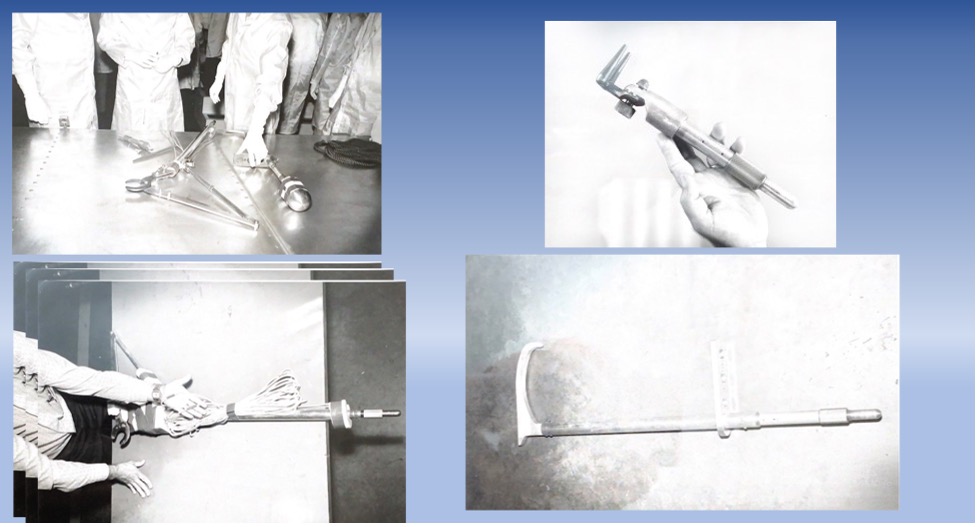

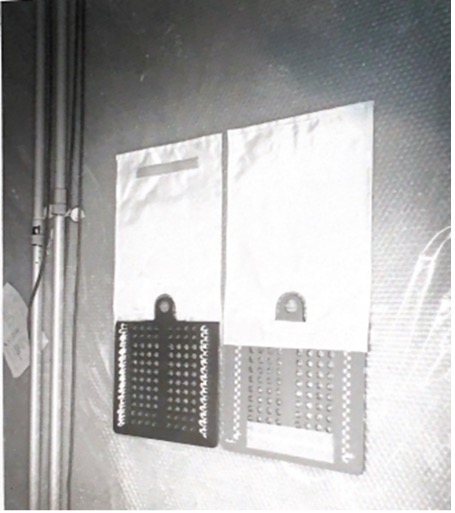

After evaluating many tools, four (4) candidates were selected for freeing the panel (Figure 8): pry bar, shepherds hook, sheet metal snips, and cable cutter (listed in ascending priority). The most attractive option was the cable cutter which was modified for “increased mechanical advantage” (via the welded lengthening of the activating cutting arm) to cut the aluminum strap. A sectional pole scheme was designed to interface with the tools and manufactured by the ME Lab shops. The pole assembly was designed using 1” diameter aluminum piping, 5-ft segments with interlocking male/female fittings on opposing ends, and an adapter for anchoring the selected tool at the running end of the assembly.

Top left: Cable Cutter Top Right: Pry Bar

Bottom Left: Sheet Metal Snips (in hand) Bottom Right: Shepherds Hook

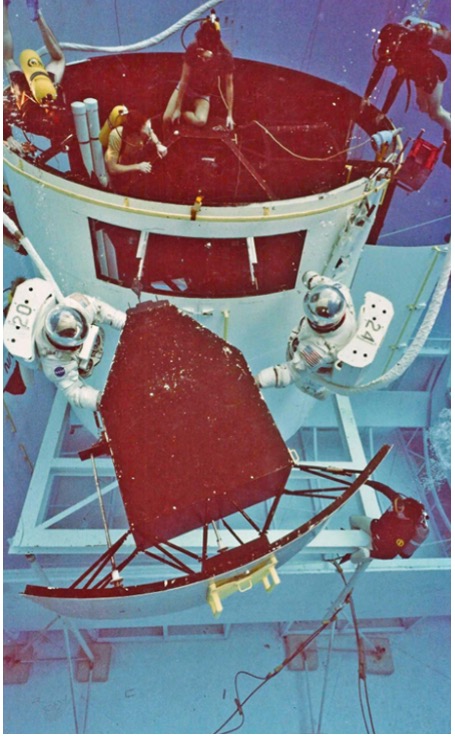

A continuous nylon closed-loop “clothes line” rope with an adapter for the selected tool on the poles, (which can be exchanged real time) all of which is activated by a crewman (EV-1) anchored in the area of the ATM in foot restraints. EV-1 provides the power to activate the cutting tool via the attached rope. Five (5) pole segments, 25-ft length, was required for freeing the solar panel. Not very “spacey”,but proved to be capable!!

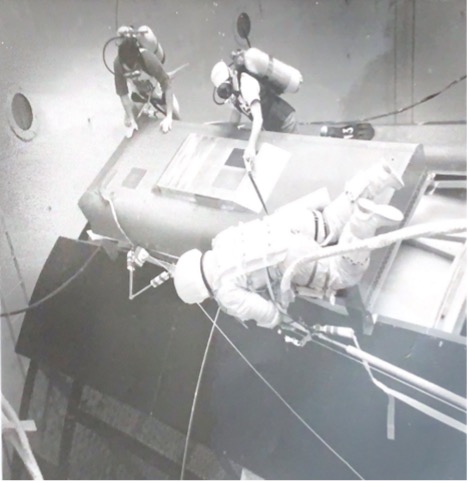

After extensive training in the NBS, the EVA operational plan was established. EV-1 would exit the OWS and airlock; traverse via pre-launch fixed handrails to a fixed foot restraint mounted on the ATM structure; EV-2 would assemble 5-ea segments of the pole assembly (Figure 9) from the Airlock area and pass to EV-1. EV -2 would then move to a sight-viewing position, adjusting as needed, and aid EV-1 in manipulating the 25-ft pole with the attached cable cutter (best option tool) to the strap area.

As an unplanned script maneuver, EV-1 told EV-2 that he was experiencing better control of the pole assembly than anticipated (thanks to weightlessness) and thought he could maneuver the assembly reasonably close to the strap. Sensor data had indicated the solar panel, in attempting to deploy, had cleared the OWS by some 6 to 8 inches, offering access to the exposed strap. After lengthy discussions on risk, collectively they decided to ease into the possibility.

A real-time pause occurred to discuss safety / recovery possibilities for EV-2 should things go haywire. The recovery plan was 2-fold: one, he could maintain his handhold on the pole and EV-1 would simply maintain his anchor position until EV-2 could safely hand-walk back to the ATM main structure; or two, EV-1 could leave his foot restraints, translate to the airlock, grasp EV-2’s umbilical and retrieve him back to safety. EV-2 said: we have a plan …. Go !

EV-1 eased the pole assembly against the side of the solar panel, maintaining pressure against the panel. EV-2, with great caution, eased down the pole length (Figures 10 & 11). EV-2 eventually was able to softly position the cable cutter jaws around the strap, while being very cautious of sharp edges that could cut the pressure suit. After EV-2 backed away a safe distance, EV-1 applied significant jerking motion pressure to the cable cutter jaws; the increased mechanical advantage was sufficient and the strap was severed! The solar panel made a positive move toward full deployment. Success!! Risky, but successful.

EV-2 maneuvering pole assembly toward strap; – – note Cable Cutter tool above EV-2 helmet

EV-2 evaluating potential usage of pry bar – – also Cable Cutter jaws around strap

The flight crew, once again, proven the value of “man-in-the-loop”!! Another “lesson learned” can be passed to the ISS! Summary: The confirmation of committed staff, monitored sensor data with engineering evaluation, open discussions, solid training, factual debriefings and man-in-the-loop for performance, produces another “WIN.”

(Note of interest: And yet another back-up: the on-board medical kit contained a bone saw. This hand-activated device had two circular rings (like key-rings) connected to an ~15” length small diameter cable which was laced with stainless steel cutting edges (like a barbed wire fence). This bone saw was wrapped into a circular pattern and duct-taped to the front of EV-2’s pressured suit just in case it was needed. How ingenious!! This device was standard equipment in the medical kit in case of a medical emergency on-orbit, but never dreamed of being used as a possible tool to salvage Skylab!

As a backup, and in case the flight crew ran into a problem, the NBS crew was underwater in full on-orbit flight configuration, tracking step by step (thanks to the air-to-ground communication tie-in with the on-orbit crewmen) to offer alternative actions if needed.

Skylab SL-2 crew, with temporary environment control and permanent power, was now operational for its full 30-day mission!

Lesson learned: In the weightless environment, EV-1 learned he could maneuver the pole assembly with an attached mass, if needed, as long as they operated very slow and cautious together!! This is HUGE!!

Given the total success of their “Save Skylab” tasks, the SL-2 crew could now turn their attention to their original mission objectives. Without going into details, the categories included scientific experiments, social interchange data, personal medical status (particularly since one of the crew is a doctor), habitat efficiency, nutrition, etc.

After 28-days on-orbit with many successes, the SL-2 crew secured the on-board systems, and in good military fashion, tidied up the habitat for its next occupants. Headed home!!

This writer, representing the entire NBS crew, was most fortunate to be invited to attend the SL-2 crew debriefing in Houston. Here are just a few of the personal points the crew made. One each cannister of shaving cream and/or deodorant for each crewman was ineffective after a few days due to pressurization loss. One bar of soap for 3-guys for 28-days – – come on, we can do better! The shower was a blessing, but the pull string to prevent water escaping from around their neck was uncomfortable and worrisome. The pressure suit dry-time after an EVA is about 10-hours. The thigh restraints at the dining table worked well. There was no problem with visual perception. The lighting was excellent both day and night, but most of the lights were mounted on the “ceiling” (oops, no ceiling on-orbit) – – need to break that habit. The reminder cues or flags at the workstations were very helpful. The crew did comment on the procedures developed in Neutral Buoyancy were extremely good; the foot restraints and handrails, strategically located, were excellent, efficient, thorough …. made our work easy and fun. Joe Kerwin made the observation: “You can replace anything that malfunctions if you have good foot restraints and good handrails to get you there.” Suffice it to say, many lessons learned in 28-days would be of significant importance to the planning and operation of the ISS.

SL-3 Launch

On July 28, 1973, Astronauts Owen Garriott, Alan Bean, and Jack Lousma were launch for their 60-day Skylab mission. It was a normal launch, filled with expectation for their docking and moving into their new Skylab home for 2-months. The OWS was comfortable and inviting for the new occupants. The crew quickly settled in and made preparations for their major EVA.

The priority task of the SL-3 crew was to install the “permanent” sun shade. This permanent sun shade would be placed over the existing temporary umbrella which was still functioning but diminishing in effectiveness. The goal was a pleasant 80-degree environment.

Sun-Shield (Permanent)

At MSFC the Materials Laboratory was given the task of determining a material that would have sufficient longevity (up to a year) to shield Skylab from the rigors of the sun for the life of the Skylab mission. Temperature swings of approximately 240℉ between daylight and night-time, which occurs every 90-minutes, emphasized the importance of this EVA.

After extensive research and verification testing, a treated mylar material, measuring 30-ft x 40-ft (1200 sq ft) was chosen as the permanent material. Arrangements were made with ILC (International Latex Corporation), the manufacturer of the Apollo pressure suits, to send two seamstresses to MSFC with their sewing machines, to fabricate the sun shield.

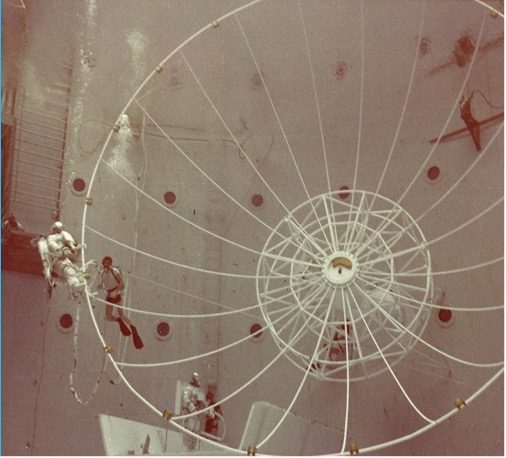

EV-1 at V-base plate on ATM super-structure

EV-1 deploying sun-shield down 55-ft poles EV-1 completes sun-shield over temporary parasol

The sectional pole assembly was the primary tool used for the permanent sun-shield deployment. A baseplate, containing a “V-shape” receptacle for securing the 2-poles required for this deployment process, was designed, fabricated, and installed on the struts of the ATM.

Crewman EV-1 would exit the Airlock area with a portable foot restraint, (designed specifically for such a need as this and stored in the OWS as standard equipment), and attach it to a permanent structure member adjacent to the V-shaped base plate. A vacuum sealed container holding the permanent sun-shield and 2-each 55-ft closed loop ropes would then be appropriately mounted at the work station. EV-2, located just outside the Airlock, would assemble 2-each 55-ft poles, attaching a pulley device (flagpole type) in the leading first pole segment and pass one pole to EV-1. A rope end would be threaded over this pulley and temporarily secured to the side of the base plate. The pole would then be secured in the V-base plate. In like fashion, the second 55-ft pole would follow the same procedure

Color-coded base with elastic loops on left /right sides

Loaded nylon rope in loops

Designer at work – – a former parachute rigger

EV-2 would relocate to an observation position for coordination purposes. EV-1 would attach the corner of the sun shield to the closed loop rope and very slowly pull the rope (some 6-8 inches) for a short deployment of the sun-shade on one pole, then on the second pole with similar motion. With each pull, the permanent shield eased from its storage container and into its deployed position. A pull on each rope perfectly controlled the “pay-out” of the shield and rope from its elastic-looped packaging (Figuire 16) design. After full deployment of the 1200 sq-ft shield over the top of the parasol (now a 2-layer configuration), all loose ends were secured at the V-base plate. After approximately 3-hrs, the sun shield was installed.

Hooray, task successfully completed!! (A note: This task required significant training and patience; a real nightmare would occur if the 110-ft of rope and the 1200 sq ft of mylar material got free from their storage container in this 0-G environment.)

A pleasant 80-degree environment now in place

Folding of Sun Shield

Packaging of Sun Shield and rope

Placement in vacuum chamber

Skylab was now fully functional for its full mission!!

During the actual deployment, the crew was very complimentary of the hardware that was provided, the procedures that were developed, and the thorough NBS training they received. The interfaces between man and machine, coupled with materials handling, paid really big dividends. And the crew so stated. It all worked really well.

As a backup, and in case the flight crew ran into a problem, the NBS crew was again underwater in full flight configuration with our own NBS test subject, tracking step by step to offer alternative actions if needed. Again, thanks to the air-to-ground communication link. No help needed!! Thanks to a solid game plan, good training, and a task expertly performed! Another valuable lesson learned for the future ISS crew.

SL-3 crew now implemented their preplanned duties on science, experiments, medical evaluations, and general maintenance on the habitat. Additional EVA’s were performed under normal circumstances and straight-forward procedures for experiments and exchange of film in ATM cameras.

The SL-3 mission duration was 59-days.

As a repeat of habitat temporary closure practices as performed by SL-2 crew, they secured the onboard systems, and in good military fashion, tidied up the habitat for its next occupants.

SL-4 Launch

The SL-4 crew, Jerry Carr, Ed Gibson, and Bill Pogue, was launched on Nov 16, 1973 for their 90-day mission. As you’d expect, they benefitted significantly from nine man-months of learning from their SL-2 and SL-3 counterparts. They had no carry-over launch malfunctions to correct so it was business as usual on their preflight plans for their mission. Their knowledge from debriefings by SL-2 and SL-3 permitted a more relaxed and proficient mode of operation in completing their broad agenda tasks.

Given the stay-time time on-orbit, their mission plan covered a much greater span of experiments for science, social, and medical data. Again, their EVA’s would be straight-forward for scientific reasons and not for habitat repair or salvage reasons.

Their final tasks in NASA’s first Space Station were 1) to gather and package experiment samples, and while on EVA, collecting samples of both metal and fabric materials that had been exposed to the harshness of the space environment, and 2) gather documents of importance in preparation for closing Skylab in a safe mode for eventual reentry. These samples/data would be analyzed and tested for ‘composition shifts’ for future space applications. Many lessons learned would be withdrawn from these samples and data for applications on ISS.

Now, it was homeward bound after 84-days! Cheers to ALL the crews!!

Summary

The three missions of Skylab set an endurance record of 171-days of manned occupancy, basically 6-months of exposure, or approaching 37,000 man-hours. Significant data from the onboard experiments and EVAs establish an impressive baseline of medical knowledge and weightless exposure. These data would be of significant benefit to designers, engineers, program managers, and follow-on crewmen for the next International Space Station (ISS) and related space pursuits.

Skylab photo by SL-3 crew as they departed for Home – – note completed repairs: Sun Shield and Solar Panel.

The image from the ATM appears to be smiling at the Crew and saying “well done!!”

Skylab Cost

The total investment in the Skylab mission is reported as $2.6 billion (document SP-4012/vol3/ch2.htm). It is humbling, yet with pride, that NBS played a significant role in its salvage and completion of such an important NASA investment

Reward for Skylab Team

Much thought was given to an appropriate recognition for our NBS team. An idea eventually evolved to send the entire team to the Cape for the SL-4 launch. That request was placed into the system. My understanding is the request eventually went to Dr von Braun. He approved the request saying: “I want everyone at the NBS, every scuba diver, suited test subject, technician, engineer, secretary, and managers that participated in the training, problem solving, and salvaging of Skylab to be present at the last Skylab launch. I want them all there.” And so it was, we were there! What a great reward, what a superb launch! The reward could not have been more meaningful nor more appropriate!! It really was special and well deserved!

Interesting and Fun Facts from Skylab

Dr. von Braun was a very committed and challenging visionary, and a fantastic leader. His heart was big, his passion contagious, his challenges were beyond this earth, and he was always selling! Here’s a couple (of many) examples:

- He would go to the Cape for a launch, would call Bonnie, his secretary, saying, “Hey, Bonnie, I’m on the NASA plane, I’ve got a guest with me, Walt Disney. I want him to visit Neutral Buoyancy to see and understand how we train flight crews for operations in space.” Bonnie would then call us saying “He’s in the air, he’ll be here shortly with a guest.” We’d make it happen!

- Other guests were much more oriented to the underwater environment, like Jacques Piccard, a technical staff member for Jacques Cousteau, a famous Swiss oceanographer, designer, and developer of vehicles to explore science and the unknowns at underwater depths of 30,000 feet. Another phone call from Bonnie saying Dr. von Braun says “I have a guest who wants to go in the tank” …. swim trunks and scuba gear were waiting for them!

- Again, it was von Braun with his salesmanship, explaining to the VIP’s, the general public, and the decision makers from Washington DC, “.…. this is how we spend our money, gentlemen. This is why, when I come to Washington and request additional funding, this is what we do. This is how we do things for future programs and future space population. This is why we need consistent and additional funding, and how we invest for our future”.

So, NBS participated in the education and the salesmanship of Space with its many challenges and successes.

According to Public Affairs, beginning in the late 60’s and for years, 500,00++ people viewed MSFC facilities via the bus tours from the Space & Rocket Center receiving insight, and some ownership, into a National Goal set by President John F. Kennedy. This was a great contribution to the general public community, and a tribute to NASA manned flight programs. The NBS and the Test Lab were major contributors to these tours. Again, something that MSFC can be very proud.

Future Usage of NBS

Now, with the Skylab mission successfully completed, how was the NBS to be used?

International Space Station (ISS)

All Skylab hardware was removed from the tank. Next, a full-scale structure of the Shuttle cargo bay was installed. For the assembly of the ISS elements on-orbit, experience was needed on materials handling of large structures. The flight crews used the NBS to develop construction techniques, tools, and procedures as a training resource for handling these large structures. All ISS modules by all countries were designed to fit within the Shuttle cargo bay. When an ISS module was delivered to orbit, if needed, the module would be “parked” awaiting delivery of its mate. The flight crews were the construction team that assembled these structures. The populated ISS was taking shape. An unbelievable on-orbit “facility” would result!

Spacelab Project

Hubble Space Telescope

The Hubble Space Telescope, representing a dream for many astronomers for many years, was launched from the Shuttle cargo bay in April, 1990. After approximately 3-yrs, a manufacturing defect was discovered in the mirror causing the all-important documentary films to be “fuzzy”. A repair on-orbit was required. Corrective lens hardware was designed and built. Replacement hardware and Astronauts came together at the NBS for extensive practice and fine tuning for their servicing mission to repair the mirror. The tools, procedures and training, worked again. On orbit, problem corrected! Hubble continues to function today!! training,

Reflections

In looking back at Skylab it’s almost like we were writing a textbook, because there were so many things that we were doing for the first time within NASA. Our experiences and successes were going to be used to help teach, and guide, and instruct, and challenge follow-on crews for weightless training teamwork. Skylab was a huge success! The Neutral Buoyancy team has been given some accolades that will be accepted on behalf of the total NBS team. Skylab is now a part of our history, but its lessons-learned are also a part of the textbook as we explore the vast resources of space, expanded knowledge, and the challenges of the yet unknown.

So, for challenges of the yet unknown, we share both history and future.

The following is considered the most significant VIP visitors in the history of Neutral Buoyancy.

\We landed on the Moon in mid-1969. In 1970 the three Apollo Astronauts Neil Armstrong, Buzz Aldrin, and Michel Collins, went on a worldwide tour as a goodwill tour, and to bring credit to the United States of what we had accomplished for all mankind.

Whenever they visited Russia, and as a part of their verbal exchange with the Cosmonauts, they posed the question and made the invitation, saying: “Why don’t you come to the United States as our guests, and let us show you around our country, including NASA? We’d love to have you visit us”. They accepted the invitation.

In Oct 1970, Cosmonauts Vitali Sevastyanov and Andriyan Nikolayev, crewmen on Soyuz 9 flight for 18-days, came to the United States, bringing along an interpreter named Barsky with them. While visiting MSFC on Oct. 20, Dr. von Braun stated he wanted them to visit and witness and possibly participate in what we were doing in the NBS.

Left to right (center): Cosmonauts Andriyan] Nikolayev, a Major General in the Russian Army, and Vitali Sevastyanov, Flight Engineer, interpreter Stan Barsky; Astronaut “Buzz” Aldrin, and Jim Splawn. An introductory briefing by Dr Matt Siebel, ME Lab Director (far left), is provided at the model of the Neutral Buoyancy facility. The Medal on the Cosmonaut’s coat right lapel identifies them as Russian Heroes

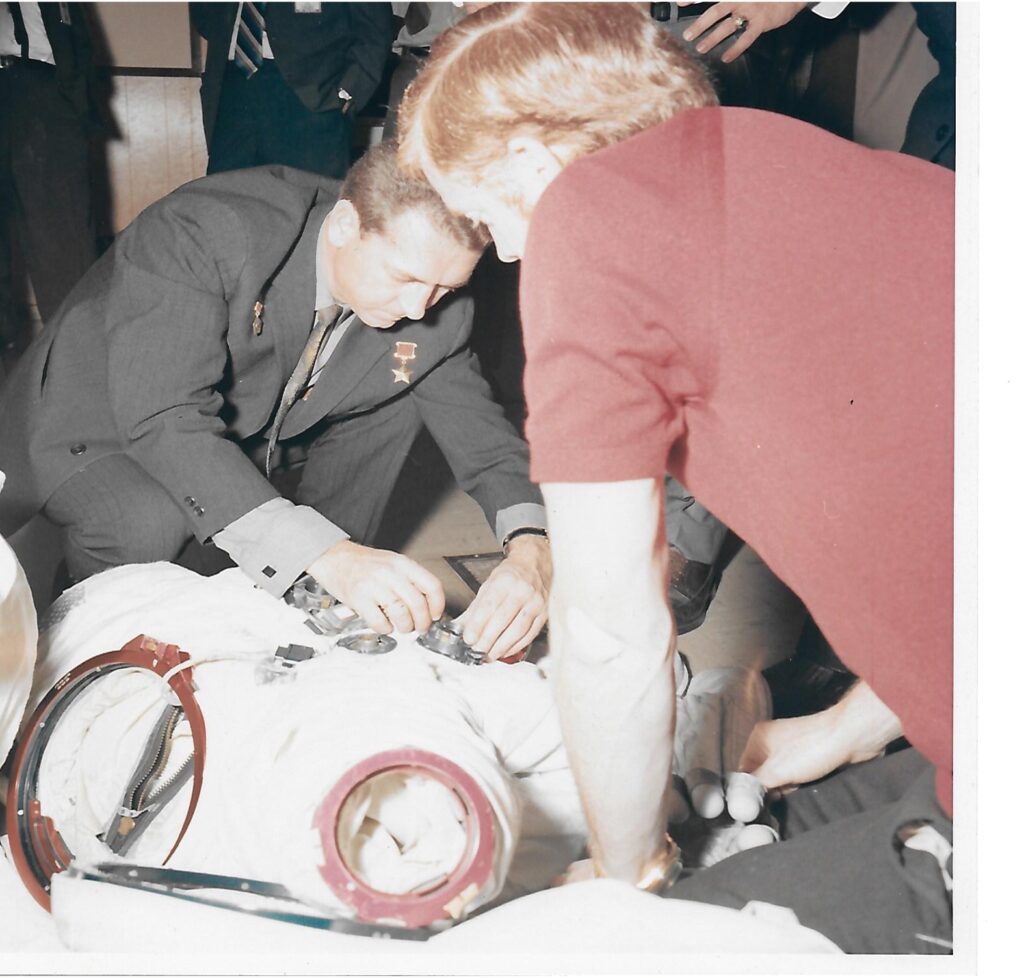

On Oct. 21, the three Russians, with Buzz Aldrin as their escort, visited NBS. Astronaut Rusty Schweickart, the guy who had done a tremendous amount of work as a backup crewman on Skylab, was our Astronaut that took the lead for this underwater experience. An Apollo pressure suit had been prepared, so Rusty spent considerable time explaining its design and functions. Of considerable interest was how the helmet and gloves interfaced with their mating hardware. Just to observe their curiosity was quite educational.

As Cosmonaut Nikolayev looks on, Cosmonaut Sevastyanov places the helmet on the neck ring. Astronaut Schweickart explains the procedure.

Cosmonaut Sevastyanov evaluates the life support system connectors as Astronaut Schweickart explains.

Jim Splawn holds Foot Restraint device as Astronaut Schweickart explains how an Apollo pressure suit interfaces with the device to firmly anchor Crewman at a work station (toe of boot slides under bridge, heels rotate outward under capture plate to complete anchor interface). L to R: Cosmonaut Sevastyanov; Don Neville, Pressure Suit Manager; Dr Matt Seibel, M.E. Laboratory Director; Astronaut Buzz Aldrin; Cosmonaut Nikolayev.

As our guests became comfortable with the explanations, the offer was made for them to participate in an underwater experience of “follow-the-leader” with Rusty. The Cosmonaut team looked at each other, nodding their heads of approval.

The attending NASA medical doctors gave Cosmonaut Sevastyanov an abbreviated physical (with Nikolayev watching closely) and released him for suit-up.

As planned, Sevastyanov then donned his Apollo pressure suit, Rusty did the same, and “the team” headed to the top deck, smiling and waving. Rusty took the lead to enter the water and allowed the divers to position the weight harness while Vitali observed. With a little caution, Vitali followed suit.

L: Cosmonaut Vitali Sevastyanov R:Astronaut Rusty Schweickart

Vitali with his safety divers

Vitali at a work station

Nikolayev was on the top deck and seriously observed every move. The interpreter, Barsky, was stationed in the control room, busily watching the TV monitor and interpreting instructions from the test conductor for Vitali.

The two safety divers assigned to each test subject moved them into Skylab hardware. Rusty continued to chit-chat with Vitali via the interpreter. After Vitali’s breathing slowed, along with his heart rate, the test director received a thumbs-up from the Doctors and the safety team, the test began.

For the next 50-60 minutes, the astronaut and the cosmonaut played follow-the-leader through the Skylab hardware, performing tasks as they traveled from station to station. The comradery between the two grew as the simulation evolved. Vitali seemed very interested in how the handrails and foot restraints provided comfortable body positioning for work. Following the test, the cosmonaut seemed most pleased with his experience. Rusty was a good teacher and Vitali was an extremely attentive student. Vitali did very good!

After approximately 3-hours at the NBS, the Cosmonaut team departed after shaking hands, nodding their heads and smiling at all operational staff they could encounter. As they were traveling to their next event, the vehicle driver asked: Do you train your Cosmonaut teammates similarly in Russia? The interpreter responded: “No, but we’re thinking about it!” What a nice compliment!

In perspective: It was surreal that in 1970 we had a Russian Cosmonaut in a NASA pressure suit following an American Astronaut while participating in an underwater test on NASA Skylab hardware for NASA’s first space station!

It was a fantastic day, just an absolute fantastic day!!

National Recognition

The Neutral Buoyancy Simulator was officially designated a “National Historic Landmark” in 1986. Wow!!

End of story

Allow me an acknowledgment on what a fantastic facility the Neutral Buoyancy Simulator turned out to be. Obviously, we received significant help from top management, Dr. von Braun and from all of his laboratory directors that worked with him and who, in turn, helped us participate in the many things that Marshall Space Flight Center and NASA has accomplished. But again, the environment that existed with Dr. von Braun and his associates was one of not micromanaging.

Let’s give everybody, everybody, enough freedom that if they have an idea, work on it, see if it’s credible, see if it’s something that is in the realm of possibility, and then go push it, go hunt it, go accomplish!! That’s exactly, if you look back at NBS neutral buoyancy, what happened for us. We were given the opportunity and the freedom to go chase a dream and a vision. It was fantastic!!

If you then look at the NBS operational period, we did significant work both inside and outside of the normal NASA boundaries that existed. But we were given that freedom. The Space & Rocket Center with the far-reaching number of people that were exposed to NASA because of not only the Space & Rocket Center facility itself being here, but the bus tours that visited daily through the Marshall Space Flight Center including the NBS; you’re talking about 500,000+ people a year back in the early ’70s that received insight into a National Goal set by President John F. Kennedy. That’s a great contribution to the general public community, and a tribute to NASA manned flight programs. Again, Marshall Space Flight Center can be very proud.

There were significant lessons learned for habitat design, for mental and medical health considerations, and operational planning, both mental and physical during Skylab missions. The efficiency and endurance of the flight crews, the stay-time of an EVA, how much work can be accomplished, how to team with each other on-orbit under very difficult circumstances, all of which were addressed in Neutral Buoyancy, and certainly a strength and an output of Skylab.

A Bit of Personal History

I was born in Upton, KY in 1933, the second of four kids; an older brother, Roland, and two younger sisters, Patricia Ann and Sibyl Joyce. My Dad was an only child and my Mother was number 14 in her family. Both were born and raised in the area of Rutherfordton and Forest City, N.C. My Dad was a Baptist Minister and my Mother’s profession was being an understanding and patient minister’s wife, along with assuring that all four kids grew into adulthood safely and educated. She did well.

Education wise, I graduated high school in 1951, Chattanooga, TN, and one year at Carson Newman College, where I enjoyed another year of football while making my decision of my profession future. Georgia Tech in Atlanta and engineering was my chosen decision. At Tech I was a Co-op (Co-operative student), a 5-yr program where students were in school for a quarter, and then an employee somewhere in industry to make sufficient funding to attend the next school quarter. My industry employment was with TVA in Chattanooga, a government organization.

My TVA exposure placed me in an office where Jo Ann Helton was secretary. You guessed it, we began dating, and were married my senior year.

Jo Ann’s family resided in Chattanooga where her Father was a lead-engineer driving the locomotives for Southern Railway for 45-yrs. With 10-kids in the family, her Mom was quite busy in shaping the lives of the kids to be contributors in life … and she did well.

Upon graduation from Tech in April 1957, I was recruited by Wolverine Tube in Decatur, AL and placed in the Industrial Engineering Office. My employment was briefly interrupted when I received my Draft Notice to report to the U.S. Army, Fort Jackson S.C. in November 1957. At the end of “boot camp” in February 1958, I was told I was being sent back ‘home’ to Wolverine, a defense supporting industry, due to my engineering degree which classified me as a “critical skill”. I was placed in the “Inactive Reserves” for eight (8) years where I completed my military service.

Beginning in 1958, Jo Ann and I began our family and were richly blessed with three (3) fantastic kids: Mike, Le-Ann, and Mark. Each completed their college degrees: Mike, an Architect, Le-Ann, an Executive Assistant, Samford University, and Mark, Business Finance. I am extremely proud with their professionalism, their contributions to their communities, and the families they are raising. They have been a huge part of our family success, and for that, I am most blessed and pleased. All three are married and have gifted us with grand, and great-grand, kids

In their early education years, they were rewarded (maybe bribed) for good school grades with a visit to the Neutral Buoyance Simulator! They loved it!! (A side note: each of our kids have a polaroid picture of them standing in a pressure suit, a side benefit of the NBS!)

After the very successful Skylab missions, MSFC management asked me to relocate to the Rocketdyne Facility as MSFC Resident Manager. At this point in mid-1974, Rocketdyne was designing, manufacturing, developing, and testing the individual components of the early phases of the Space Shuttle Main Engine (SSME). Our family relocated for a 3-yr assignment. This period of service is covered in the neighboring document “SSME Resident Management Office, Rocketdyne”.

Employment History:

- Wolverine Tube: April 1957 – May 1961

- NASA / MSFC: Jun 1961 – Jan 1984 – (Retired with 30-yrs service counting the government service with TVA)

- Spaceco Electric: Jan 1984 – Dec 1988 Founded construction company – – sold company

- Boeing: Dec 1988 – Jul 2010 – (Retired with 22-yrs service)

Summary

The three missions of Skylab set an endurance record of 171-days of manned occupancy, basically 6-months of exposure, or approaching 37,000 man-hours. Significant data from the onboard experiments and EVAs establish an impressive baseline of medical knowledge and weightless exposure. These data would be of significant benefit to designers, engineers, program managers, and follow-on crewmen for the next International Space Station (ISS) and related space.

Skylab Cost

The total investment in the Skylab mission is reported as $2.6 billion (document SP-4012/vol3/ch2.htm). It is humbling, yet with pride, that NBS played a significant role in its salvage and completion of such an important NASA investment.

Reward for Skylab Team

Much thought was given to an appropriate recognition for our NBS team. An idea eventually evolved to send the entire team to the Cape for the SL-4 launch. That request was placed into the system. My understanding is the request eventually went to Dr. von Braun. He approved the request saying: “I want everyone at the NBS, every diver, technician, engineer, secretary, and manager that participated in the training and problem solving for Skylab to be present at the last Skylab launch. I want them there !” And so it was, we were there! What a great reward, what a great launch! The reward could not have been better nor more appropriate! It really worked superbly!!

Discussion

Dr. von Braun was a very committed and challenging visionary, and a fantastic leader. His heart was big, his passion contagious, his challenges were beyond the sky, and he was always selling! Here’s a couple (of many) examples:

- He would go to the Cape for a launch, and would call Bonnie saying, “Hey, Bonnie, I’m on the NASA plane, I’ve got a guest with me, Walt Disney. I want him to visit Neutral Buoyancy to see and understand how we train flight crews for operations in space.” Bonnie would then call us saying “He’s in the air, he’ll be here shortly with a guest.” We’d make it happen!

- Other guests were much more oriented to the underwater environment, like Jacques Piccard, a technical staff member for Jacques Cousteau, a famous Swiss oceanographer, designer, and developer of vehicles, to explore science and unknowns at underwater depths of 30,000 feet. Another phone call from Bonnie saying Dr. von Braun says “I have a guest who wants to go in the tank …. swim trunks and scuba gear was waiting for them.

Again, it was von Braun with his salesmanship, explaining to the VIP’s, the general public, and the decision makers from Washington DC, this is how we spend our money, gentlemen. This is why, when I come to Washington and request additional funding, this is what we do. This is how we do things for future programs and future space population. This is why we need consistent and additional funding, and how we invest for our future.

Future Usage of NBS

Now, with the Skylab mission successfully completed, how was the NBS to be use?

All Skylab hardware was removed from the tank. Next, a full-scale structure of the Shuttle cargo bay was installed. For the assembly of the ISS elements on-orbit, experience was needed on materials handling of large structures. When an ISS module was delivered to orbit, the module would be “parked” awaiting delivery of its mate. The flight crews were the construction team that assembled these structures. The populated ISS was taking shape. The flight crews used the NBS to develop construction techniques, tools, and procedures as a training resource for handling these large structures.

The Hubble Space Telescope, a MSFC program, representing a dream for many astronomers for many years, was launched from the Shuttle cargo bay. After an extensive on-orbit soak, a manufacturing defect was ultimately discovered in the mirror causing “fuzzy” of the all-important documentary films. A repair on-orbit was required. Corrective hardware was designed and built. The flight crew practiced extensively in the NBS in the 1993 timeframe for their servicing mission to repair the mirror. The training, tools. and procedures worked again. Problem corrected. Hubble continues to function today!

REFLECTIONS

In looking back at Skylab it’s almost like we were writing a textbook, because there were so many things that we were doing for the first time. Our experiences and successes were going to be used to help teach, and guide, and instruct, and challenge follow-on crews for weightless training teamwork. Skylab was a huge success. The Neutral Buoyancy team has been given some accolades that will be accepted on behalf of the total NBS team. Skylab is now a part of our history, but its lessons-learned are also a part of the textbook as we explore the vast resources of space, expanded knowledge, and the challenges of the yet unknown.

So, for challenges of the yet unknown, we share both history and future.