by Duane Counter

Recollections on My Adventures in Space Travel, 1958-1989

As I sit down to begin this, I wonder why I’m doing it. The main reason is just to refresh my memories—I don’t think anyone will want to read this, except possibly my family, and much of it will be totally uninteresting, except to an engineer and I doubt even to an engineer because much of what I am about to describe is now stone age engineering, even if it did get man to the moon.

Expedition to Alabama

It was a cold day in December. We were newly-weds, living in a basement apartment in Manhattan, Kansas. Joyce was working as an assistant dietitian in the Manhattan hospital and I was studying for finals. It was my 9th semester in engineering. My priority wisely emphasized romance (my wife of 45 years is proof of that) to the penalty of my grades, so I had to go another semester. A couple months earlier, Convair, the big aerospace company in Los Angeles, laid off 3000 engi- neers and the job prospects were decidedly poor. I interviewed all the possible companies that came through Kansas State but the mailbox contained no job offers. The summer previous I had worked on the an- cient B47 bombers for Boeing in Wichita with a caretaker group, keep- ing track of the drawings and fielding maintenance and modification questions on the aging fleet while the newer and larger B52’s rolled off the assembly lines. The Boeing runways were parallel with the Air Force base runways next door, separated by a chain link fence. The B52’s often took off from the Air Force and Boeing runways simultane- ously. The Boeing pilots thought they were better than the Air Force jet jockeys and it was fun to see two test pilots drag race the huge B52’s.

Every time a new B52 came off the assembly line, all the employees would line up outside and proudly see “my bracket” take off, but most of the time I spent trying to find if a new camera could be mounted in the RB47 reconnaissance version. When I couldn’t find the correct drawing I just went down to a hangar to a parked RB47 and sketched up a new bracket.

Two events were the highlights of that winter. Joyce announced that she was pregnant and Sputnik was launched. I won’t talk about the first event but for the second we were dressing for the fall formal, the Duad, which the PiKA’s held with the Sig Ep’s. The little clock radio in the kitchen interrupted music for a special announcement. The Russians had launched a tiny earth satellite and had beaten the United States in the first step in the space race. The satellite didn’t do anything except emit a radio signal; “beep, beep” it went. Sort of a “nah, nah, nah, nah, nah, nah” to the US. The US had been trying to launch a satellite in a Navy program called Vanguard and they had a series of disasters, blowing up on the launch pad. Joyce and I got dressed in my tux and her formal At the dance, I told everyone there what had happened and only one person showed the slightest interest—Gary Hilton, a fraternity brother of mine who shared my interest in science fiction. The next day, every newspaper in the country had banner headlines about Sput- nik and then everyone was interested, but that night, no one cared a flip.

The dance attendees were not alone in their ambivalence about the possibility of space travel. The engineering program at Kansas State sponsored a series of guest lectures and one of them used his appear- ance to prove that it was impossible to place a satellite in earth orbit. The accuracy was beyond any guidance system that could be built and any launch would send the satellite off into space or burning up into the atmosphere. That ranks right up with Professor Gold from UCLA who proved that any man on the moon would sink out of sight in the miles of deep dust. That’s why he got the nickname of Gold Dust. But that gets ahead of my story.

So there I was, studying for my finals and looking forward to a little time in York, NE with family for Christmas when the phone rang. The little girl on the other end said that I was being considered for a position with Redstone Arsenal. I interviewed with them when they came through and didn’t remember much of what they said, probably because they didn’t say much. Redstone was run by the Army and everything was classified. The girl asked if I could come to Alabama for an interview. I asked if they would pay for the trip. “Oh no.” Since it was 1000 miles and almost no interstate, it would take me three days each way and one or two days for the interview. I couldn’t afford to take out eight days from studying for my finals. The possibility that I might borrow the mon- ey to fly down never occurred to me. I told the girl I couldn’t afford to come on my own and asked the girl if I would still be considered for the job. She was incredulous. “Well, I don’t know but suppose so.” I hung up and forgot about the call. A few days later I got the telegram: “You are offered a GS5 position as engineer with Redstone Arsenal at $4480 per annum. Call (phone number) to accept.”

That was the only offer I got until after I moved to Alabama. I received a late offer from Boeing in Seattle to do documentation. The previous semester, the average engineering graduate at Kansas State received 50 job offers. At my graduation there were engineers walking around saying “I don’t know what I’m going to do. I didn’t get any job offers. Guess I’ll go to graduate school.”

So Joyce and I packed everything we had into a 4×7 Uhaul, bumper hitched to our 52 Hudson, and headed south in the midst of a snow storm. We stopped in Topeka to move the load forward and stopped twice more to have the bumper welded back on. Entering Alabama, we first saw tenant shacks in the cotton fields and in Huntsville began a search for somewhere to stay. Our apartment in Manhattan had rented for $55/month. We assumed that this was severely inflated because of the demand of a college town and naively expected to rent a furnished house for that in Huntsville. Enter the boom town. All the good places were un-furnished, already rented and twice that high. New houses were sprouting overnight. After a couple fruitless days of searching I called Mom and told her “We wouldn’t put hogs in some of the places they show us.” I remember a barn of a place with high ceilings and exposed 60 watt bulbs hanging from long wires in the ceiling and a smell! Thoughts of going back to York to work in the Elevator entered my mind.

We asked the motel agent what we should do and he said “Try Athens or Decatur”. Athens, the cultural center of ancient Greece! I liked the name. There was promise there. I clearly remember driving up Clinton Avenue with a canopy of oaks overhanging the street. What a warm welcome they gave us that cold January day. We found this little duplex at 708 N. Madison for $37.50/month. For that we could afford to buy furniture! It wasn’t much. Later, on a spring day, as we were pre- paring for our first dinner guests, termites thought they were also invited to the party and swarmed the living room through cracks in the door and window trim. Joyce didn’t know what they were and ran to our neighbors on the other side of the duplex to find out. She blocked their entrance with masking tape and swept up the bodies just before the invited guests arrived.

We took the remaining money from my father’s inheritance and bought a stove, a refrigerator, a kitchen table and a bedroom set. Our living room furniture consisted of a card table, one card table chair, a stack of wedding gifts still in their shipping boxes topped by a drafting board and a table cloth, and a hi-fi set (monaural, before the days of stereo). We had a washing machine that mother had replaced with a new one because it had a broken transmission. I paid for Mom to ship it down and repaired the transmission.

That old apartment had a lot of “charm”. It had un-vented gas heaters that emitted quite an odor we didn’t trust without adult supervision. The windows panes no longer remembered any friendship with putty and were retained with nails driven into the sashes. I had considerable respect for whoever nailed them in without breaking glass. On our first Christmas we went back to Nebraska with 6 month old Doug and shut down the heat as we left. While we were gone, the temperature dropped below freezing in Alabama. One day out on the return trip we called Will Ed and Nancy, our neighbors, to go over and turn on the gas. When we came in the front door we could hear the water running. I went into the bathroom and met a geyser shooting upward where the pipes to the old fashioned claw tub met the floor. Fortunately, the bath- room had a little “step down” of an inch which confined the lake to the bathroom and the lake was draining through holes around the pipes in the floor.

I ran outside, shut off the water at the meter and rummaged through my tool box for a big lead weight which I hammered into the fractured pipe and shut off the flow. The next day the black plumbers underneath the house gave us an experience into another language we totally could not understand—not a word!

We returned from Nebraska where the houses had central heat and our six month old crawled in warmth on carpeted floors and we resolved to find a better place to live. On Valentines Day in 1959 we moved into our first new house at 610 N. Hine Street.

Werner Von Braun

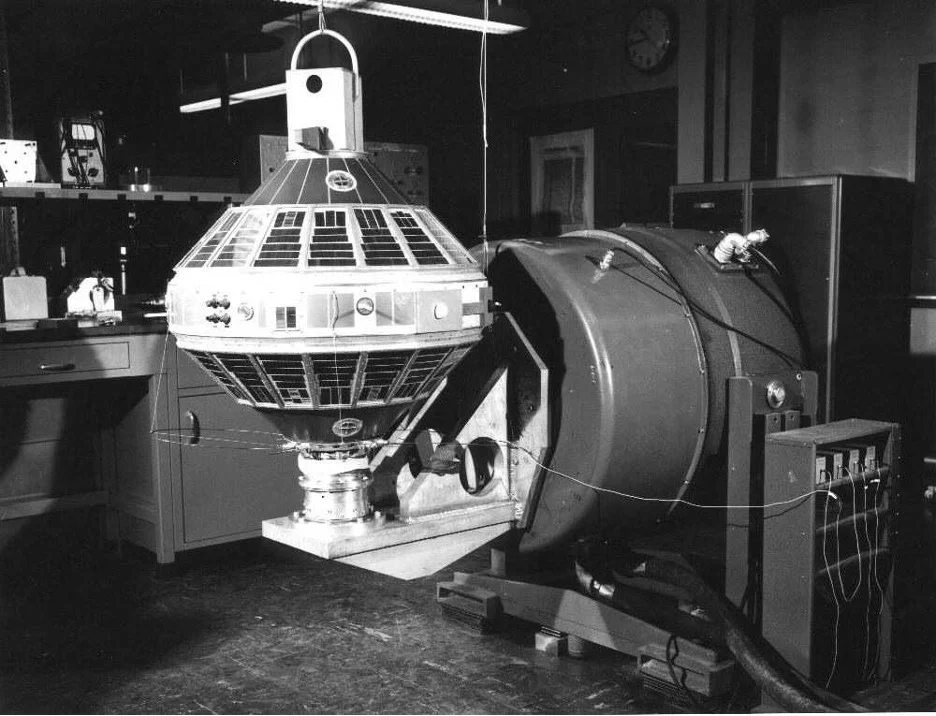

I went to work at Redstone Arsenal on February 3, 1958, a Monday after the first US Satellite, Explorer 1, was launched on Saturday and I went to work for the group that designed that satellite. I was privileged to work on Explorer II and all the rest of the satellites launched by the US through 1960 when Goddard Space Flight Center was founded and assigned responsibility for designing the US Satellites. It was a fantastic time.

When I was very young I wanted to be an airplane pilot. In the seventh grade we studied careers in school and I changed my career plans because I found out that airplane pilots only made $10,000/year. I decided if I couldn’t fly them I would be an aeronautical engineer and design them.

One semester before graduation I got a summer job working for Boeing, really expected that they would hire me and I would work at Wichita, relatively close to home. But here I was in this “foreign” country and working for foreigners in a highly classified job. My German bosses were brought here by the Army from Peenemünde, a village of northeast Germany on an offshore island in the Baltic Sea. It was a center for the development of guided missiles, especially the V-1 and V-2, prior to and during World War II.

Werner Von Braun was quite an engineer. He was a wonderful manager and loved to get his hands on hardware and talk to the people actually doing the work. He used to show up at the labs unannounced and would go into the shops or the testing labs and talk to the lowest guy doing the hands-on work. All the managers in between would have a cow.

“Don’t tell me that man doesn’t belong out there. Man belongs wherever he wants to go—and he’ll do plenty well when he gets there.” Von Braun

They often over-reacted to comments he would make. He would make a suggestion or just a comment and the next thing you would know, a new project was started to design, build and test something he mentioned. One time I was working on the Apollo Telescope Mount which had a very demanding requirement for accuracy, pointing to 1/10 arc second, and a tiny temperature change could throw it way off. Von Braun said he was flying in his plane and when the windshield iced up he just turned on a windshield heater and wires imbedded in the glass heated up the windshield. The next day, people were buying aircraft windshields and testing them!

When I first came to Redstone, the people I interviewed couldn’t tell me much about what they were doing or what I would be doing because everything was classified, When I asked a supervisor in a design group what he did, he showed me a circular fitting with holes in it and said “I design things like this.” When I said “what’s that and what does it do?” that’s all he would say. I interviewed supervisors of a mechanical de- sign group, an electrical design group, a testing group and an analysis group. The analysis group sounded most interesting so I agreed to hire in there. I didn’t know these people designed Explorer I. I didn’t know much of anything about what they did.

I entered the Arsenal though a guard shack, obtained a temporary pass, went through another guard shack into a barbed wire enclosure, past another guard into the building, and then requested an escort to my office. I had to have an escort to go to the bathroom. For two weeks while my temporary interim clearance was being obtained two of us who hired in at the same time just sat in a room and read a dictionary.

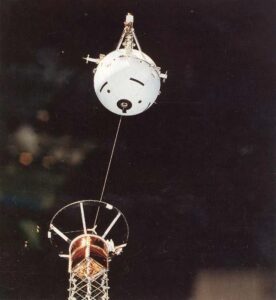

When my secret clearance came through, I was set free and was assigned the first analysis task. I had to come up with an experimental way of determining the pitch moment of inertia of Explorer II. This satellite with its expended last stage rocket was about 5 feet long and 7 inches in diameter. I told them to tie a string to each end and suspend it from the ceiling and start it swinging, each end in the opposite direc- tion. Then use a stop watch and determine it’s period and calculate the Moment of Inertia from the pendulum equation. Quick, dirty and very effective. My bosses were impressed. “Where did you get those equations?” I showed them my Vibrations course manual. My bosses were from the mathematical derivation school. Start with differential equations, describe the physical system, develop the exact equations and solve it. I did a lot of that.

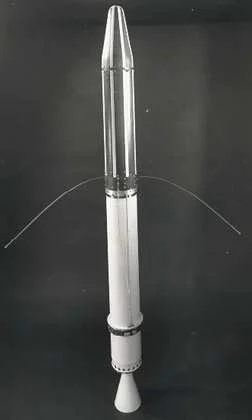

I did a lot of work with spinning satellites. The upper stages of the Redstone rocket were spin stabilized. There was a bearing supported platform that was spun up before launch to 450 RPM. The upper stages were all solid rockets. First a nest of eleven then three and finally one, all identical solid rockets. The satellite and empty case of the final solid rocket entered orbit spinning at 450 RPM. This caused some problems. Left alone, the spinning rocket would eventually transfer to a wobbling, nutating body as the kinetic energy dissipated and finally go into a flat spin. Since the satellites had radios transmitting the experimental data, the antennas didn’t like changing attitudes and signal strength would fluctuate with the spin. You could see it on the records of the radio signals. It was easy for the electronic engineers, knowing the antenna pattern, to tell me how fast it was spinning and at what angle of nutation. How could you predict this change? How long would it take for a satellite to transfer from its initial spin attitude to a flat spin. This was the subject of my Masters Thesis some years later (A Study of Attitude Change of Space Vehicles, Masters Thesis, University of Alabama 1963 ). It was a good subject because I was the expert and I had the experimental evidence to support the theory, so no university professor could give me much static.

We must come up with some way of de-spinning the satellite into a stable spin and design larger antennas. The first satellite de-spin idea was two wires with weights that were reeled out. This would do two things. Like the ice skater who brings her arms in to speed up her spin, reeling out the wires with weights would slow down the spin and the wires could be used as radio antennas. It was my job to calculate the weights on the end of the wires to achieve a specified final spin rate. Just a matter of conservation of energy and conservation of momentum. Got to dissipate that energy. Just attach a tube of rubber or Teflon on the base of the wire. It will flex back and forth and dissipate the energy. Final spin rate was determined by conservation of momentum.

On a later satellite we wanted to do more de-spinning so we added another method. The large antenna with weights would still be used but as a second de-spin stage. The satellite was much larger than Explorer I. It was about 3 feet in diameter, a big double cone. For a first stage de-spin we attached two wires wound around the outside with weights. This contraption would unwind very rapidly and would fly off when fully unwound. This method could not only de-spin but could stop it and spin it up in the other direction. Again, by the principle of conservation of momentum. The external weights had to be precise or the de-spin would be too much or too little. We made the weights a little oversized and when the satellite was fully assembled and at the Cape for launching, they attached it to an old burned-out upper stage and put it in a spin fixture which measured its spin moment of inertia exactly. They called me the night before the launch and I calculated exactly how much the weights should weigh. A technician then drilled out just so much lead before the launch.

I have often wondered what happened to the weighted wires flying off into space. They were like miniature bolos at 17,000 miles per hour. I thought about those the first time an astronaut went EVA. He could have his head cut off if one of my de-spin devices came around. Undoubtedly they burned up and re-entered years before.

There was another advantage of the double cone satellite. Its greatest moment of inertial was about the spin axis instead of the pitch axis as with the earlier Explorer I. Therefore, energy dissipations would cause a stabilizing influence instead of destabilizing and the dynamics would not change from spin about the axis of symmetry to a tumble. To fur- ther stabilize the motion, we designed an energy dissipation device consisting of a donut of steel partially filled with mercury and mounted around the nozzle. The mercury sloshed around and dissipated any accumulated motion to bring it back into a pure spin.

Slides Ruled!

When I went to work at Redstone, it was before the age of computers, it was before electronic calculators. It was in the days of slide rules! I remember Helmut Pfaff holding up his slide rule and telling me in his thick German accent, “This is how I fought the war,” The government issued me a 20 inch slide rule! Wow! It could get another place of accuracy. When I went to graduate school and brought in my 20 incher the other students resented it and thought I was cheating.

Then we got electrical calculators. They were big noisy electro- mechanical machines the size of an electric typewriter. You could add, subtract, divide and multiply. I had a Marchant and my office mate had a square root Friden. There was a lot of pride, “my machine is better than your machine”. On his calculator you could press one button and get the square root of a number but on mine you could transfer the result of one calculation back to the keyboard and use it in another calculation. I had to use the “fives method” to get a square root. Today, I don’t remember how to do that. We did matrix calculations with huge tables, big sheets of paper, a lot of chug-chug.

This was also before Xerox. Reproduction was with carbon paper! Or some blue stuff that faded and smelled of ammonia.

Procurement was simple. You didn’t need hundreds of copies and specs for everything. If you needed a bolt, you wrote a requisition and took it to the local hardware store. No quality control department, no procurement department, no inspection. On one flight, we had problems with leaking electrolyte from the batteries. We didn’t have time to procure new batteries. They were about the size of your thumb and five inches long. So we wrote a procurement for a gross of condoms, Trojan brand. Edwina Portwood, the secretary, was embarrassed to type up the procurement request but the condoms worked. We only used about six. Wonder what happened to the rest.

Eisenhower, Nixon and Kennedy

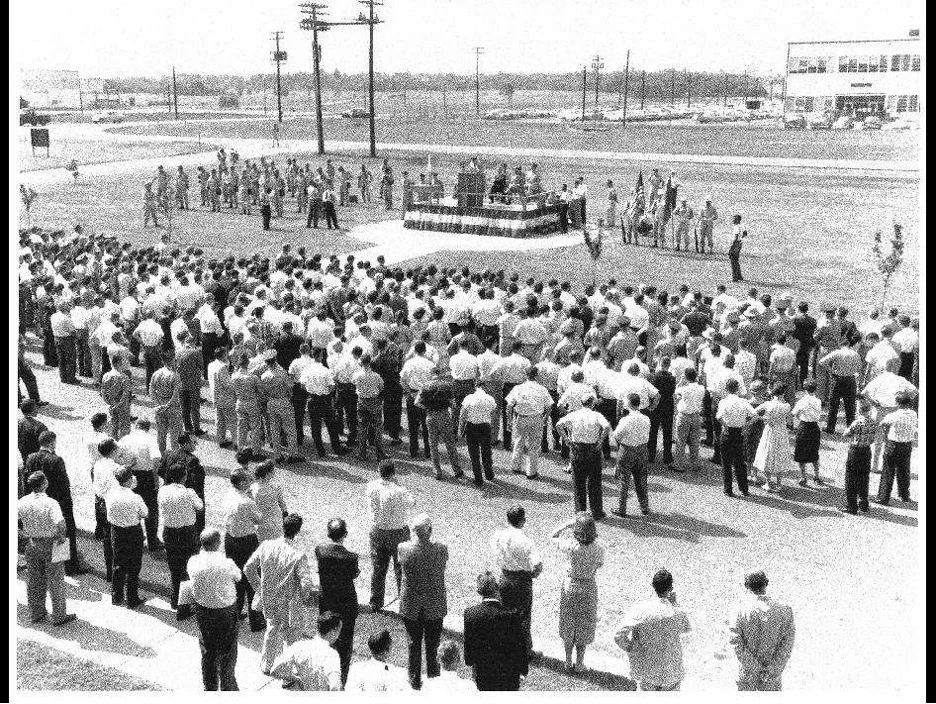

In October 1958, Eisenhower proposed the creation of the National Aer- onautics and Space Administration (NASA). Redstone Arsenal was divided up into Army activities and NASA activities and Marshall Space Flight Center (MSFC) was formed. We were given a choice to transfer to NASA or stay with the Army. Almost everyone transferred unless they were working on an exclusively Army project. They carved out MSFC in the middle of Redstone Arsenal. President Eisenhower came to MSFC to dedicate it to George C. Marshall, the founder of the Mar- shall plan that reconstructed Europe after the second world war. It was fun to stand at the side of the road as Ike rode by in an open convertible and to stand in the crowd as he addressed employees and dedicated MSFC. A number of other presidents came to MSFC. I saw Nixon and Kennedy in similar visits.

Under the Army, almost all documents were either Confidential or Se- cret and you dare not leave anything out when you left your office for any reason. We had classified file cabinets with a big steel bar in the front and a changeable combination padlock. Two signatures were re- quired to open or close them every day. If the signatures weren’t there, a security guard would call you from home to come in and check and lock everything. When MSFC was founded, it meant great changes. The guard shacks came down, and everything was declassified except the thrust of the Saturn V rocket. Not long after that, even the Saturn V thrust was declassified. A big truck came to the lab every week to shred the classified documents. I still had my secret clearance when I retired but I never again saw any classified material.

Stratoscope II

Stratoscope II was a helium filled balloon launched at dusk from Red- stone Arsenal. A telescope was suspended from the bottom, supported on a mercury filled spherical bearing. We were responsible for the ther- mal control and the telemetry systems of the experiment. Two engi- neers that worked for me spent all night in a trailer monitoring readings and sending up heater control commands. The next morning was a Sunday. The telescope came down in a tree in the front yard of a black country church in Mississippi. The parishioners thought it was some kind of divine retribution. We were concerned about environmental contamination with all that mercury, much of which spilled on the ground. NASA folks got in, cleaned it up and got the experiment out as soon as possible.

Preparing for Man in Space

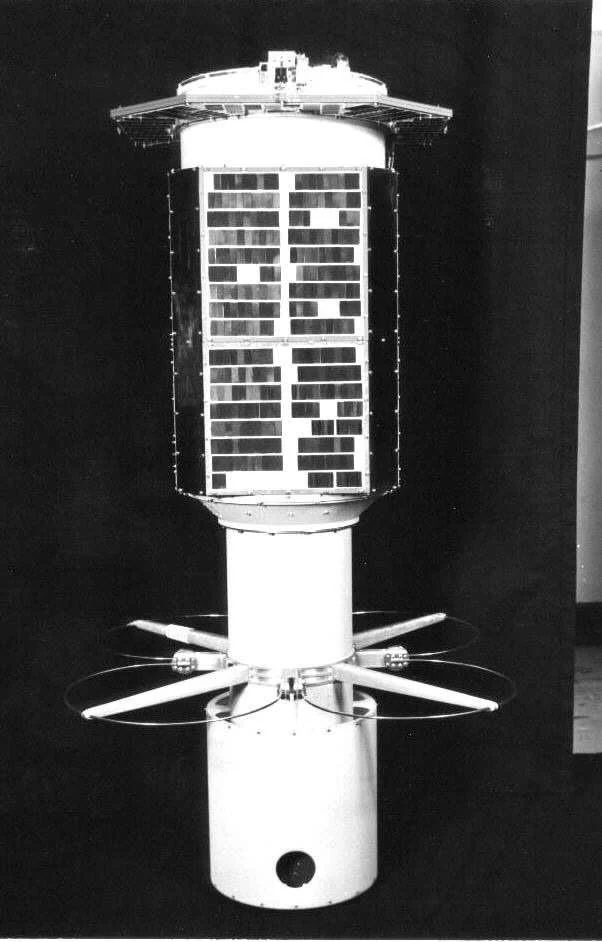

After MSFC was founded, we began to think of man in space. One of the concerns was the risk from micro-meteoroids. Would a man be killed by a meteoroid crashing through his spacecraft, puncturing it and maybe even drilling a hole through him? The Pegasus satellite was designed to get experimental data on the size of meteorites and the possibility of their occurring. It had two large folding wings with panels of aluminum sheets and foam core. Each of the panels were electrified to make a large capacitor. They were built with a spectrum of aluminum sheet thicknesses and were tested in a laboratory with various sized projectiles to find what size of particle would penetrate each panel. Electronics sensed penetration and a high voltage burned the short to recharge the capacitor.

Three of these big satellites were launched, starting in February 1965 and they stayed in orbit for years, gathering a lot of statistically significant data which has been used ever since to design manned space craft.

The interesting part of the project for me was the design, analysis and test of the mechanism which deployed the big wings. The wings were hinged panels, connected in a scissor mechanism. They were deployed by a “Harmonic” motor drive that had a one stage 300:1 gear mechanism, hermetically sealed from the vacuum of space. The transmission was developed by United Shoe Corporation in a little town outside Boston. It was developed for use in their shoe factory and they modified it for use in space. It used a tin can with an internal gear tooth. The can was deformed to an oblong shape by a pair of rollers so that it meshed with a smaller diameter internal gear one tooth different. 300 teeth meshing with 299 teeth gave 300:1 gear reduction! By putting the drive motor interior to the can, the motor/transmission was hermetically sealed.

I was responsible for analysis of all aspects of the project. I did dynamic analysis of deployment, stress analysis of all the mechanisms and structures, vibration analysis of the package subjected to the launch environment, thermal analysis of the electric motors, etc. Really fun—I loved it.

The greatest thrill was looking at video pictures beamed back of the deployment in space.

There were two big solar panels on the side of the craft which provided electrical power. They were deployed by spring power and that was also a fun analysis. Deploy, bounce, but don’t break.

I didn’t have much to do with the early manned space flight vehicles except the guidance system. I worked in Astrionics Laboratory which designed all the guidance, control and communication electronics. The division I worked for was a mechanical design group imbedded in an electronic laboratory. Our group did electronic packaging, converting the electronic circuitry designed by the electronic engineers into black boxes. One branch did circuit board design. By this time, I was a supervisor and had two civil service employees and, at the peak, over 30 contractor employees directly working for me. The group performed stress, dynamics, thermal and vibration analyses and I had stress signature authority for the Lab. Every drawing had to be signed by me. Astrionics Lab designed the Instrument Unit (IU), the stage which was the brains of the Saturn first stage rocket. You may have seen the shots from space when the IU separated from the second stage and entered the exhaust flame from the second stage. I did some research on air bearings as support for the gyros as part of the guidance system. This was very interesting—fluid flow equations in various types of air bearings.

The circuit board design group spearheaded the technology of multi- layer circuit boards. One of the problems they had was inspection of the internal layers of a “sandwich” of several layers of circuit board. If you x-rayed the board, the various layers would all blend together and you couldn’t detect any problems with any one layer. I worked with the designers to come up with an x-ray technique which utilized a rotating table to mount the circuit board on and another rotating table to mount the x-ray film on. By adjusting the rotation geometry, it became possi- ble to “focus” the x-rays on any slice of the circuit board. This tech- nique was later applied by Vanderbilt Medical center for the X-ray of a human brain to locate a tumor. Technically, this was the precursor of modern day CAT scans.

Kennedy gave his famous “man on the Moon in this decade” speech and it was more than NASA really wanted or thought we could live up to but Von Braun acted as if Kennedy had called his bluff and went out to do it. The biggest risk was that we had to eliminate a number of baby step unmanned launches and go for broke almost the first time. I think we were lucky but everyone busted a gut to get it right the first time.

One of the great sensory experiences was to stand on the hill and watch the test firings of the Saturn V. The sheer magnitude of sound was awesome but what you noticed most was the feeling in your stom- ach. The low frequency vibrations seemed to resound in your intes- tines. I was fortunate to be able to attend a number of launches at the Cape. They took a plane load of NASA employees to the cape to see a launch as rewards for good work. The early launches I saw were Sat- urn 1 and then Saturn V. I flew down in old chartered prop driven DC3’s. We usually didn’t spend the night and sometimes delays in launch made a long day. Then they would take you to an orange stand to buy oranges to bring home. The most spectacular were the night launches of the Saturn V.

After man got to the Moon and Congress decided that we had “done that and got the T-shirt” they cancelled all funding for future trips to the Moon and we scrapped the giant Saturn V. Sad.

14

Roll Tide!

Not long after I hired at Redstone, the University of Alabama founded the Huntsville Center and began advertising for students among the employees at Redstone. My boss approached me and suggested that I look at courses there with an eye to an advanced degree. The government would pay for tuition and books. I enrolled in a masters program and completed all requirements available in Huntsville. At that time, they wouldn’t let anyone get a degree from UAH. Degrees were conferred from the Tuscaloosa main campus for which you had to have at least 12 hours on campus. So in 1961, with two boys (Mickey was six months old) and a brand new Buick we moved to Tuscaloosa for a semester. I was paid full salary plus tuition and books and felt especially privileged among the typical struggling students. When we came back home in January 1962 I went back to work and tried to write my masters thesis at night. Sharon was born September 1962 and when Joyce became pregnant with Julie in March of 1963 she gave me an ultimatum: get that thesis written before this baby is born. I created a hideaway in the bedroom away from the TV and children, finished the thesis and received my MS in Engineering Mechanics in August of 1963.

Skylab

When the Apollo program was scrapped we had a lot of leftover Saturn boosters. What could we make with the extra Saturn V hardware? Various design studies were performed and they concluded that a Saturn IB stage could be emptied of internal hardware and used as a space station. Von Braun always wanted to have a space station; he said it would be “as big as a two bedroom FHA house”. The Sun was nearing the eleven year maximum of solar radiation so science could be per- formed using telescopes to study the Sun. In 1966, the Apollo Telescope Mount (ATM) and Skylab1 projects were born.

Our branch was given responsibility for a lot of the mechanical portions of the ATM. Power was first. There had to be solar arrays—really big solar arrays. We drew on our experience with the Pegasus project for the concept. There would be four huge wings, each with scissor mech- anisms, which would deploy the arrays. They would have five pages per wing and twenty solar panels per page. Each little panel was about 10 inches by 20 inches and they each ended up costing $10,000 just for the solar cells. That’s $40m worth of solar cells.

The wings were powered by a variation of the Harmonic drive but this time it was developed by another contractor. The panels were clamped together to withstand the launch environment. We had little sheer plates of hardened steel to transfer the sheer load between the panels. These were mating male/female plates with tapered edges that transferred sheer load just in one plane but allowed motion in other planes. The whole stack was held together with very high strength latches that were released pyrotechnically on command on orbit. Because of the increased safety factors required by manned space flight, we had to design these redundantly (two charges were used) and with high safety factors. The pyrotechnics were spec’ed at +100, -20%. They had to be able to operate at 80% charge with the most extreme of temperature, resistance, etc. but they had to function and not break with two charges going off at +100% output each. Then the astronauts came in and said, “What if they were disconnected and we went EVA an they went off when my head was in the way?” So they had to remain intact operating without any resistance with two charges at +100% overcharge and we had to demonstrate it.

Analyzing the stacked solar array for the extreme launch vibration environment was a trip. At that time the biggest computer we had was an IBM 7094. The first computers we had were built using vacuum tubes but this was one of the first transistor-based main frames. Our group used a structural analysis program called NASTRAN developed for NASA. It took punched card input and our analysis really taxed the computer. It would run for hours and hours, usually in the middle of the night.

We did a lot of testing to prove out the design. First we vibrated individual solar panels with various design thicknesses, skin thicknesses, core designs, etc. and we also put them in acoustic chambers and tested in the extreme sound environment of liftoff. We built a small stack com- posed of one fourth of an array, five pages each 1×5 panels and tested that. A vibration test article was built consisting of a full-size wing with everything but solar cells. The solar cells were simulated with aluminum plates cut to the dimensions of the glass cells and cemented to the aluminum substrate. This was taken to Wyle Labs in Huntsville and was fully instrumented with thousands of strain gages and accelerometers and subjected to the full launch vibration and acoustic environment. Pages and pages of data were analyzed and compared with analysis predictions.

The transportation vehicle also had to be tested It was required to ship the solar array stack by truck. A shipping enclosure and a wagon to ship the wings to the cape were designed. It had to be tested. A test article was built and the test wing was mounted inside and it was run over curbs and the most gosh awful speed bumps you ever saw to try to simulate the National Transportation Board specs for truck transportation. We were concerned about the driver in the Semi cab because he bumped his head on the cab roof. The shipping container was re- quired to have thermal and humidity protection so insulation and air- conditioning unit with humidity controls were designed. They ended up shipping the wings to the cape by air in the Super Guppy aircraft.

A very interesting aspect of the design verification was verification of the deployment. Since the wing deployed in zero G it was not designed to withstand its own weight on Earth so we had to come up with some way of testing the deployment. A big steel I-beam frame with air bear- ing beams supporting each of the five panels on their edge were de- signed. The air bearing surface was a tray with poured plastic con- structed to be perfectly level and smooth. The wing deployment was tested in one G without sacrificing any confidence in verification. The wings only had air resistance that would not exist in space.

I also was responsible for analysis of a number of other parts of the ATM. We did the analysis of the Control Moment Gyros that rotated the ATM in space to point the telescopes at the Sun, the Charger Battery Regulator Modules that converted the solar array power to the voltage required by the ATM, and the Hydrogen Alpha telescope that was the pointing telescope for the experiments. I also worked on the Goddard X-Ray telescope. This was a glancing incident telescope. The “lens” was a hollow steel cylinder. The inside was very slightly conical so that X-rays could bounce. Anything greater than a very small angle and the x-rays are absorbed instead of reflected. So a very slight angle was machined and then another slight angle and the x-rays bounced a cou- ple times and focused way back in the telescope.

The difficult systems problem with the telescope mount was thermal so you had to keep all the heat out and thermal control the rest. This re- sulted in a lot of tiny heaters, sensors and insulation.

I was called in to investigate a failure in the zoom camera lens for the Hydrogen Alpha pointing camera. A zoom lens, whether for a space telescope or a Nikon 35mm camera is designed the same way. There are several lens elements that are moved using cams following spiral tracks. The cams are usually just pins. The lens for the space camera was lubricated with moly-cote dry lubricant. It would jam halfway in it’s motion. I took the drawings and did a simple calculation of the friction and cam force during the travel and found that they had violated stand- ard rules governing cam design. They flew me to Bethpage New York and I spent a couple hours convincing the designers and suggesting a design change. After the meeting the vice president said he had a couple tickets to a Broadway play (Promises, Promises) that night that he couldn’t use and would I like to use them? I naively agreed (accepting gratuities is illegal) but I was not arrested.

Some exciting and some fun things happened after the ATM and Sky- lab were launched in 1973. The first was a disaster. Our solar arrays were not the only power supplies on the station. The Skylab also had its solar arrays and power supplies but we didn’t have anything to do with them. Actually, management asked us to design them but “our plate was full” and my boss declined. We said that If we had designed them they would have worked. I think they were designed with much lower margin and less analysis and test verification. At launch, one of the Skylab solar arrays ripped off taking a micrometeoroid and thermal shield with it. They were somewhat flimsy and without the arrays MSFC went into disaster recovery mode. I didn’t have to get involved in this, thank goodness. The Structures and Materials Lab across the street was responsible and they worked 24 hours a day trying to come up with a solution. The launch of the astronauts to man the Skylab was delayed until a solution could be built and tested. The first problem was that the solar arrays tore off some insulation and the Skylab was over- heating. With half the power and the insulation gone they were facing a near disaster. Hundreds of patches and fixes were devised, tested and discarded. A fix was devised whereby astronauts would go EVA and attach a tent to reflect the sun’s rays. It was dangerous. What kind of ragged edges could tear the astronaut’s suits? Could it work? They rapidly configured various tent designs and tested them in the MSFC “swimming pool”, the neutral buoyancy simulator the astronauts used to train in and test EVA concepts . The solution worked and they succeeded in deploying the half of the array that was intact, albeit with some difficulties and much holding of breath.

We always said we designed the solar array that worked.

After the astronauts boarded the Skylab, one day I was in the control center and the attitude control team couldn’t understand the readings they were getting. The whole vehicle was wobbling around. Was the attitude control system going haywire? They called the astronauts on orbit and asked them if they were noticing anything strange. They said everything was OK—one of the astronauts was getting his exercise. He found out he could run around the inside of the Skylab on the electronic boxes, making his own gravity by centrifugal force. They told him to stop.

Then one day one of the redundant Charger Battery Regulator Modules (CBRM) malfunctioned. A relay was stuck. I got a team together in- cluding the engineer that did the vibration analysis on the unit. The electronic engineer said that if the relay got a shock it might free up. We looked at the offending relay and took a test CBRM down to the vibration lab and instrumented the relay with a little accelerometer. We then took a standard astronaut hammer and hit the outside of the CBRM in the neighborhood of the relay. We hit it in several places until we found the spot that shook the relay the most. Then we went back to the control center and called up the astronauts and told them to go EVA and hit the relay “four inches from the top and seven inches from the left side. Raise your hammer about five inches from the CBRM an give it a good whack.” He did and the CBRM started up again!

The Skylab was host to a number of astronaut teams and provided immense advance in science about the sun2 despite the fact that due to a lot of delays in initially launching it didn’t make the solar peak year but was launched in a solar minimum year.

Hubble Telescope

I was privileged to be in on the early concept studies for the Hubble Telescope. At first it was called the Large Space Telescope. MSFC hired an astronomer who had been head of an observatory as a consultant. I took a course he taught on optics for astronomical observatories and telescope design. One of the most interesting parts of this was the structural design of the large optical mirror. I was one of the team which evaluated proposals from the competing contractors. There were two designs: glass “welded” into an open honeycomb construction and a “hogged out” design which started with a big block of glass 6 feet in diameter. Holes were ground into the back to lighten it. I preferred the hogged out design because of uniformity of structure without stress ris- ers but the other design won the contract, mostly for other reasons. The glass was like pyroceram with near zero coefficient of thermal expansion. There were a lot of proprietary processes involved with the two competitors. During the construction, the chosen contractor had a disaster and a big mirror blank was broken. I was called in as part of the “tiger team” investigating the failure.

Space Shuttle

The division I had worked for in Astrionics Laboratory was a mechanical design group in an Electrical/electronic laboratory. The mechanical design laboratory across the street had always been jealous of our work and thought our division should be a part of their lab. Our division director, a German named Josef Boehm, was highly respected and managed to retain his group and function until he died of cancer. A couple years later, the group was broken up.

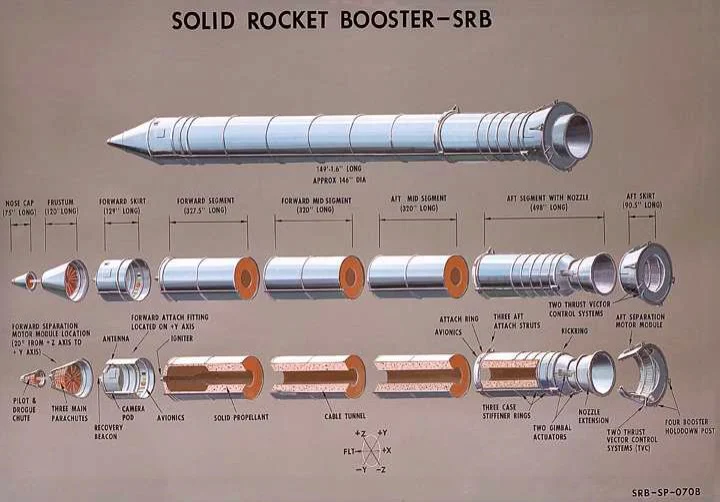

In 1974 the Director of MSFC formed a small group to do systems integration for the for the Space Shuttle Solid Rocket Boosters. Every design group was doing their own thing and things were getting disconnected. I was reassigned to this group. My people were all reassigned to divisions in the mechanical lab.

The SRB cases are segmented, made using a unique manufacturing method starting with an ingot of steel. The hot ingots are kneaded like a blob of dough. Imagine taking a blob of dough and poking your thumb in the middle of it. Roll it from the inside around and around until you push it out to a thin cylinder. Male and female joints are machined into each edge. That is how the SRB cases are made. Then several structural segments are bolted together with an O-ring seal between to make a casting segment. A casting segment is then filled with the solid propellant fuel in a thick cylinder. The fuel is mostly rubber and alumi-num powder with the consistency of automobile tire rubber.

I did a lot of trade studies on diameter of the cases, how many segments should or could be manufactured, case wall thicknesses and how many structural cases to a casting segment.

The Shuttle represented a totally new way of thinking for NASA—a re-usable space vehicle The Orbiter is flown back, washed off and re- flown. The design for multiple flights was one thing but the SRB’s had to survive impact in the water, not sink, and survive the corrosive effects of salt water and towing back with a tug. The selected SRB case metal is a high carbon steel similar to tool steel. This is not something that is good to immerse in salt water.

And how do you design for water impact? How big are the waves and how does the wind contribute to the design? What about the parachute loads?

Saturn was designed for three sigma loads. The Loads group performed statistical analysis and 2.2 sigma or 99% probability loads were published. These were applied with a 1.4 factor of safety on yield. When statistical probability of strength inherent in the standard material strength tables is taken into account, this gave us a very low statistical probability of failure. We felt this was very appropriate when the safety of a man’s life was involved but there was no man aboard when the SRB’s hit the ocean. Failure would only result in the loss of a case. We could afford to lose one once in awhile. This was an entirely new way of thinking—cost effective design.

We developed statistical load distributions for all the post separation events to optimize for cost effectiveness Instead of 2.2 sigma loads, we needed complete statistical load distributions and combinations of loads. For the parachute loads, a drop model was constructed and full scale parachutes were built and dropped with a range of wind con- ditions. Loads vs. wind, angle, etc. were tabulated .

For the water impact loads, a drop model was constructed and they set up a test location in the Tennessee River and dropped it from a crane with a spectrum of vertical velocity, horizontal velocity and impact angle.

We obtained statistical metrological data for the drop site (probability of wind and gusts, probability of various wave heights, water currents and directions) and statistical data on the probability of strength. If a part is manufactured of a particular type of aluminum which has a published strength, what is it’s statistical strength? The published ma- terial yield and ultimate strength is lower than its probable actual strength. What will it really break at? I wrote a Monte Carlo computer program incorporating all the load matrices and probabilities and pro- duced load probabilities for each of the parachute and water impact loads.

Then I wrote another Monte Carlo program to determine attrition rates and a queue type production model to determine how many units had to be procured, given an attrition rate and a flight model (how many launches per year an how many months turn around to re-fly a case).

Since this was early in the design process, a lot of trade studies with different designs were performed.

3. SPLASH (SRB Probabilistic Loads for Attrition of Subsystem Hardware) Program Description and Users Manual SE-019-171-2H Dec. 3, 1979

4. SPLASH Evaluation of SRB Designs NASA TM X-64910 October 1974

5. SRB Water Impact Velocity Trade Study NASA TM X-64997 April 1976

6. SRB Attrition Rate Study of the Aft Skirt Due to Water Impact Cavity Collapse Loading NASA TM X-73308 April 1976

7. SRM Attrition Rate Study of the aft Motor Case Segments Due to Water Impact Cavity Col- lapse Loading NASA TM X-73303 May 1976

I was the systems analysis engineer for the Thrust Vector Control Subsystem and SRM Nozzle. A lot of analysis and coordination was per- formed between the MSFC designers of the actuators that rotate the nozzle and Thiokol who manufactured the SRM and nozzle. I was at Kennedy Space Center on a control console monitoring the tests of the SRB prior to the first shuttle flight but wasn’t high enough in the pecking order to be on the console during the launch.

The Challenger accident occurred while I was working for TOS. On the day of the launch it was too cold. I always criticized Thiokol (the SRM contractor) and SRB project management because I could never get them to test the SRB to the design limits. For example, it was required to deflect the nozzle to a square pattern of +/- 5 degrees or 7.5 degrees in the corners. They did a number of static firings at their plant in Utah and I asked them to deflect the nozzle to the limit on at least one test firing and hold it there for a few seconds just to prove that it would survive the limits. They always replied that we would never see that in flight. But that was the design requirement. I always pushed for testing to the requirement. The same thing applied to temperature. The motor was required to function at 30 degrees. They did a lot of testing in cold weather in Utah but they mounted the motor on a railroad car and kept it in a heated building and rolled it out very quickly and fired it before it could get cold. One of the reasons was that the thrust from the motors was temperature dependent and a cold motor might not produce the required thrust but it was required to produce the thrust even at the limits of temperature. It was never tested cold. So on that day, I was very concerned because it had never been tested below freezing.

However, I am not convinced that the cold temperature really caused the accident. I think assembly processes damaged the O-rings. I have seen the technicians take 2×4’s and pry the oblong cases to put two cases together and I suspect one of them pressed against the O-rings and damaged them. A lot of good managers took the blame and re-signed as scapegoats over that.

TOS

I worked on the SRBs through STS-9 and in May 1984 I was offered the Lead Systems Engineer position (basically Chief Engineer without the title) for the Transfer Orbit Stage project.

It was really one of those “offers you can’t refuse”. I had worked for the project manager before. I was given the responsibility of conducting the Preliminary Requirements Review the week after I joined the team. It was a case of sink or swim. The man I replaced hung around for a week to help me out and then I was on my own. The Transfer Orbit Stage was an “upper stage” which flew in the Shuttle bay and was used to push a satellite from the 200 mile orbit of the Shuttle up to synchronous orbit or used to send a probe outside the earth’s orbit, like to Mars.

I worked on TOS from 1984 until my retirement the day after my fifty-fifth birthday in December 1989. I took TOS through Preliminary Design Review and Critical Design Review and it was qualified and ready to fly when I retired. It had two launch missions: the Advanced Communications Technology Satellite and Mars Observer. Both of these missions were successful as far as TOS was concerned. The Mars Ob- server payload failed when it got to Mars but that was long after TOS did its thing and got it there.

The prime contractor for TOS was Orbital Sciences Corporation (OSC) and their prime sub-contractor was Martin Marietta from Denver. OSC primarily performed engineering management but the engineering was performed by Martin so I spent a lot of time in Denver.

Tiger Teams

Whenever a significant failure to a project occurred, the management formed a “Tiger Team” to investigate. Experts in several disciplines were called in and sent to the appropriate contractor’s site to investigate the failure. I was called in on a number of these. One that was most memorable was a failure of the Inertial Upper Stage (IUS). The IUS was developed in partnership between NASA and the Air Force. In the beginning of the Shuttle program, the Air Force wanted the Shuttle to launch secret spy satellites. NASA said, “bring money”. In order to share the cost, the Air Force agreed to develop an upper stage to boost satellites from the Shuttle orbit into synchronous orbit required by communications or spy satellites. The IUS was the result.

When one of the IUS missions launching a billion dollar satellite went way off course, the Air Force launched an investigation. The contractor, Boeing, and the subcontractor for the motor could not find out what caused the failure. Then the Air Force sent in a team and they all had theories but none were convincing. So they called on NASA. Since I was working on the TOS and it used the exact same rocket motor, I and several of my engineering team were assigned to the tiger team. We went to the contractor’s site and were given presentations from the two contractors and the Air Force on each of their theories and then were given “free reign” to look at anything. We asked for all the test firing data, looking for a design deficiency.

After two weeks of pouring over reports and data I found a thermocouple measurement inside the nozzle bearing that suddenly took off hot. I asked the contractor’s engineers what was their explanation of the high reading. They said it was a failed measurement. I said, “Wait a minute. Thermocouples will fail in only two ways: open or short. They don’t wander off. That is a good measurement and you got a hot gas leak. It didn’t destroy this bearing but the next time it could.” They all agreed that this was the cause of the missile failure. The bearing insulation was redesigned. The NASA tiger team was dismissed and neither the Air Force nor Boeing admitted they didn’t get the answer.

Awards and Ata-boys.

In addition to various sustained superior performance awards there are some awards I particularly treasure: a letter of commendation from Werner Von Braun in 1960 for the satellite de-spin design, the NASA Exceptional Service Medal for Skylab in 1973, NASA Medal for Exceptional Engineering Achievement for Solid Rocket Booster design for reuse in 1981 and a Director’s commendation for Transfer Orbit Stage in 1989.

It is very interesting the sequence of events that led me to a wonderful career. God closed all the doors to my plans for working for an airplane company and opened only one door and I had to take it. I had no idea what was behind that door but it was man’s greatest adventure in my lifetime, man going to the moon. It was always fun and every day was new—I never worked on the same problem twice.

Duane Counter 2002